Wacker and Gearbox Biosciences agreed to collaborate to advance plasmid DNA manufacturing technologies. By combining Wacker’s expertise in GMP manufacturing of biologics, including pDNA, with Gearbox Bioscience’s solutions for antibiotic-free plasmid proliferation, this collaboration seeks to address these challenges while aiming to set new industry standards, according to Ralph Krafczyk, PhD, nucleic acids expert at Wacker R&D.

“This collaboration underscores our commitment to continuously enhance our proprietary PLASMITEC® toolbox in order to provide even greater benefits to our clients, who develop cutting edge therapies that are aimed at improving the life of patients worldwide,” says Krafczyk.

Wacker previously developed an antibiotic-free system for recombinant pharmaceutical proteins, leveraging its ESETEC® (E. coli secretion technology) platform. The joint effort with GEA will focus on workflows for antibiotic-free plasmid DNA manufacturing and difficult-to-produce pDNA products. The collaboration is focused on delivering solutions that are more sustainable than current technologies, while also providing superior quality and reduced timelines, adds Krafczyk.

“Our proprietary Pop-Out-Plasmid® technology is already in use in antibiotic-free protein production and now we are applying it to plasmid production as well,” notes Arvi Jõers, PhD, co-founder and CEO of Gearbox Biosciences. “Eliminating the risk of spreading antibiotic resistance through pDNA is a great relief for regulatory agencies and society.”

Both Krafczyk and Jõers point out that the collaboration is already underway, with initial milestones including the evaluation of Gearbox Biosciences innovative Pop-Out-Plasmid technology within the PLASMITEC toolbox. The partners stress that they are committed to fostering a culture of innovation and collaboration, with the shared goal of advancing the field of biologics manufacturing to improve the accessibility of raw materials for the development and application of next-generation therapies, and to facilitate clinical translation from bench to bedside.

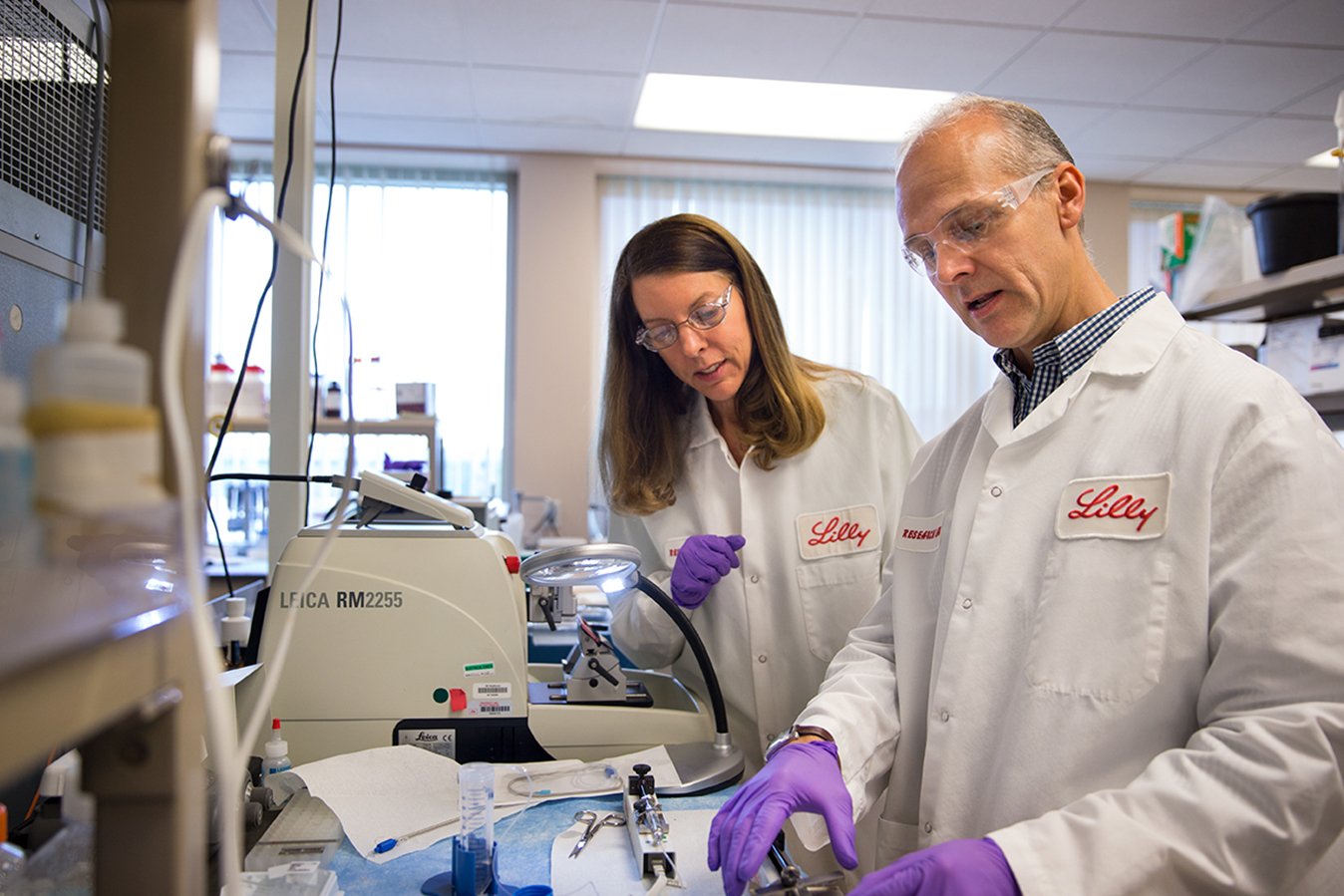

Work on the collaboration will be carried out at the recently opened Wacker Biotechnology Center at the company’s central research and development site in Munich.

The post Wacker and Gearbox Biosciences Join Forces on Plasmid DNA Manufacturing appeared first on GEN – Genetic Engineering and Biotechnology News.