At the Bioprocessing Summit in Boston today, Cenk Undey, PhD, recently appointed iCMC Digital Transformation Program Lead at Sanofi, challenged the audience to look “beyond digital” toward a future where data, artificial intelligence (AI), and automation fundamentally reshape how biologics are developed and manufactured.

Undey illustrated the shift with a childhood story from Turkey’s Gökçeada island. As a boy learning to fish, he was frustrated when fish stole his bait. The breakthrough came when he found old goggles and peered underwater, suddenly able to predict rather than guess. “That’s what AI does for bioprocessing,” he said. “It replaces guesswork with prediction.”

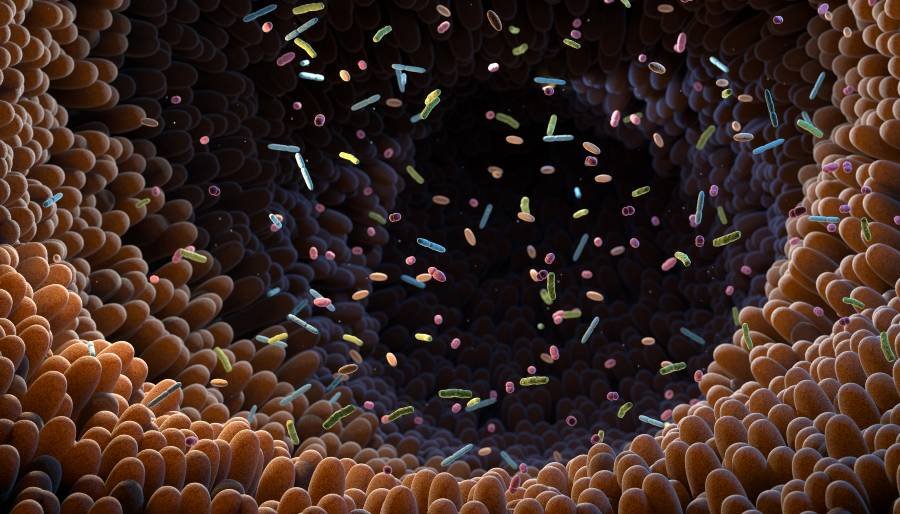

That predictive leap is essential as the industry moves from Biotech 3.0—defined by a surge in new modalities in the 2010s—into Bioprocessing 4.0, where advanced analytics and machine learning merge with intensified, automated systems to make development faster, smarter, and more cost-effective.

Undey pointed to three case studies that demonstrate the impact:

- At Amgen, deep learning accelerated cellular image recognition, shrinking analysis time from 40 hours to just three.

- Smart manufacturing pilots showed that machine-learning–driven feeding strategies improved cell growth and titers.

- In silico modeling reduced a formulation robustness study by 24 days, transforming trial-and-error work into targeted experimentation.

Sanofi’s own journey, launched in 2020 under the “iLab” initiative, is now scaling across 2,500 users, 100 labs, and 20 sites covering biologics, synthetics, and vaccines. The program’s scope includes process modeling, generative AI, robotics, and automation—all underpinned by digital transformation. But, Undey emphasized, success depends as much on people as technology: “You need the right people in the right roles. Upskilling and reskilling do not happen organically.”

The vision is a self-optimizing ecosystem, where labs evolve from reactive to proactive, and ultimately anticipatory—much like self-driving cars. Beyond speed and efficiency, the payoff includes greener footprints, lower costs, and higher quality.

“Don’t jump into fancy solutions unless they’re scalable,” Undey cautioned, before returning to his fishing metaphor: “the challenge is no longer whether we can catch more fish, but how quickly we can teach the whole village to see beneath the surface.”

The post Harnessing Data and AI to Revolutionize Bioprocessing Beyond Digital appeared first on GEN – Genetic Engineering and Biotechnology News.