Although much of bioprocessing still relies on large stainless-steel bioreactors, many biotherapy manufacturers are also turning to much smaller, single-use platforms, and that could be just the beginning of a shift toward even smaller-scale solutions. At the recent Himmelfahrtstagung on Bioprocess Engineering 2025 meeting held in Bremen, Germany, Cedric Schirmer, PhD, deputy head of the bioprocess-technology section at the Zurich University of Applied Sciences in Wädenswil, Switzerland, and two colleagues from Levitronix, which produces magnetically levitated motor technology without bearings, reported: “Recent trends in process development favor miniaturized, parallelized cultivation systems to enhance throughput, reduce material consumption, and improve process understanding.”

No matter how bioreactors evolve in size, cells need stirring. For example, Schirmer and his colleagues pointed out that “stirred bioreactors are essential for developing and commercializing biopharmaceuticals using microbial or mammalian systems,” including recombinant Escherichia coli or Chinese hamster ovary (CHO) cells. Variations between cell types, though, often require different specific geometries of a bioreactor and how cells are stirred. Developing a process for a specific application starts on a benchtop bioreactor.

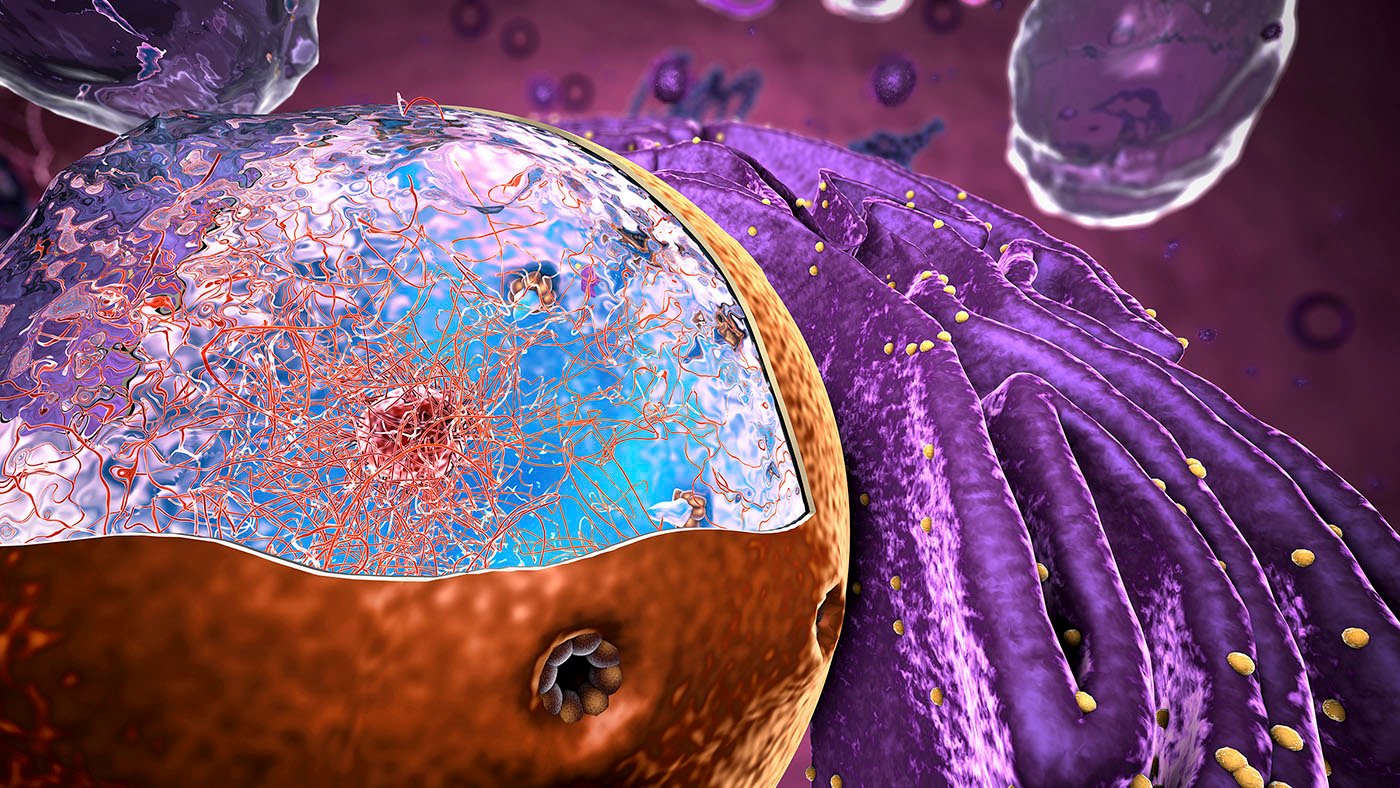

Schirmer’s team developed a benchtop bioreactor that can handle milliliters to liters. Instead of a shaft-driven stirrer, this bioreactor uses levitation. The stirrer basically floats at the bottom of the bioreactor, where it is kept in place and rotated with magnetic fields.

In a poster presented at the meeting, Shirmer and his colleagues showed that their levitation-based stirring worked for cultures of E. coli and CHO cells. As they stated, “Comparable cultivation results and similar cell-specific IgG production rates (qIgG) were observed in the reference system HyPerforma Glass,” which relies on conventional stirring.

So, why switch to levitation for stirring? Schirmer’s team pointed out several potential benefits. For one thing, the lack of a shaft penetrating a bioreactor should reduce the risk of contamination. Plus, these scientists pointed out that their bioreactor “effortlessly adapts to varying environmental and cultivation requirements without the need for modifications or different bioreactor setups.”

In many ways, flexibility is the key benefit of this levitation-based bioreactor. In addition, Schirmer and his colleagues stated that “process engineering data confirm that the newly developed bioreactor system is suitable for cultivating both shear-sensitive animal cells and robust microbial strains.” This change in stirring technology might be used in many ways, especially when developing a new bioprocess.

The post Miniaturization with Bioreactor Levitation appeared first on GEN – Genetic Engineering and Biotechnology News.