Trenchant Biosystems released multiple internal and independent external data readouts for the prototype of its AutoCell CGT manufacturing platform. Company officials say they expect the AutoCell platform to reduce CGT vein-to-vein timelines from its current industry-standard time of six weeks to only 2.5 days through automated manufacturing and QC.

The data demonstrate that the AutoCell platform can manufacture CGTs with a 7-fold increase in gene-modified cell yield compared to existing technologies and reduce cost by up to 80%, according to Jon Ellis, CEO, who added that the data also demonstrate that AutoCell could make typical clinical doses and in-process and release testing with 25% of a fresh apheresis collection.

“The wider industry has run out of patience for the cell and gene therapy to deliver manufacturing practices resulting in therapies to large-scale patient populations in an affordable manner. To date, this is still theoretically, but not practically, possible. Manufacturing is still too lengthy, labor-intensive, and costly to deliver CGTs to patients,” he contended.

The data also indicate that the platform “could pave the way for CGTs for the first time as first-line therapies,” he added.

Trenchant completed its internal validation process using five fresh apheresis sourced from healthy volunteer donors. These were processed in the prototype within 36 hours of collection. The apheresis were washed using Trenchant wash buffer, and Trenchant’s micro bubble protocol completed single-step T cell selection and activation, prior to transduction with a GFP lentiviral vector.

Trenchant has now achieved performance targets for washing, selection, and transduction unit operations with its prototype platform and processing cassettes, continued Ellis. Additionally, the activation of T cells has been shown to be controllable, ensuring optimal levels of expression of CD25+ and CD69+ activation markers, key predictors of lentiviral transduction efficiency, he pointed out.

Trenchant also completed external validation of certain data with Invetech, which designs, engineers, and manufactures customizable platforms based on client needs. Invetech’s testing successfully demonstrated that the AutoCell platform can perform critical process steps (washing, selection, activation) with good process controls, providing a valuable validation of the platform’s core functionality, said Ellis.

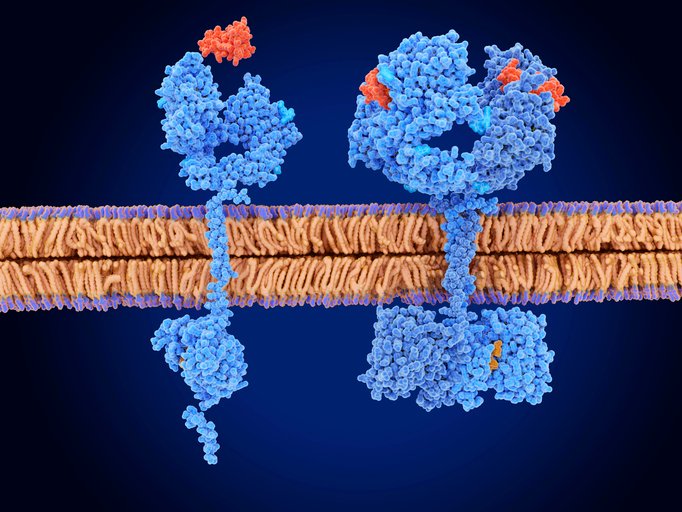

The CGT manufacturing process uses proprietary technologies to remove the current requirement of costly and lengthy ex vivo expansion of CAR-T cells to produce a clinical dose, Ellis pointed out.

The reduction in cell loss from the data showed that AutoCell could use whole blood as a potential source material, not needing the more expensive, invasive, and challenging apheresis, stated Ellis. Trenchant BioSystems anticipates having a whole blood protocol completed and data release out in early Q2 2026.

The post Trenchant BioSystems Reports Multiple Data Readouts from AutoCell CGT Manufacturing Prototype appeared first on GEN – Genetic Engineering and Biotechnology News.