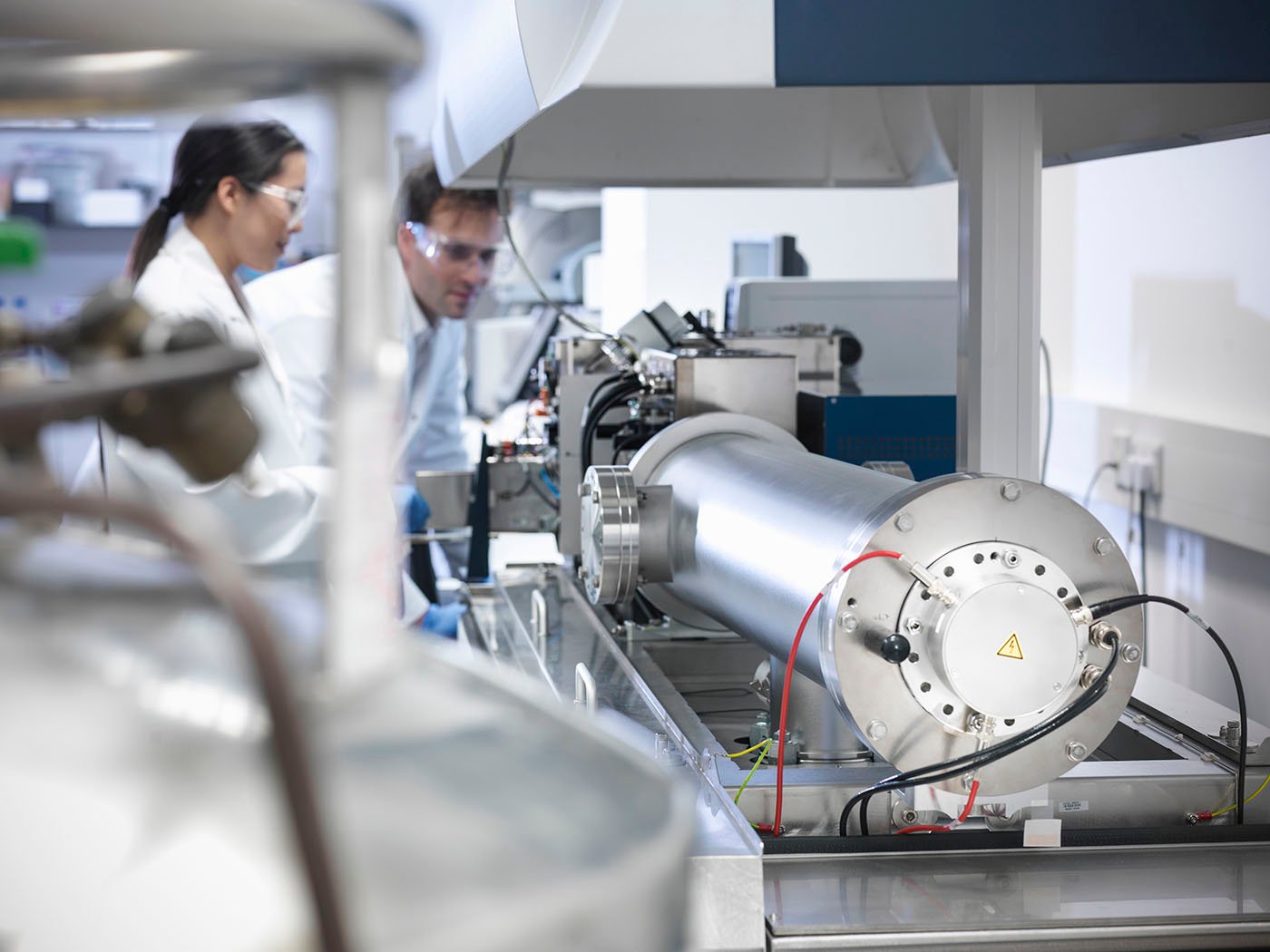

Mass spectrometry (MS) has long been a cornerstone of chemical and biological analysis, but in biotech and biomanufacturing, it is now experiencing a renaissance. As drug modalities diversify—peptides, siRNAs, mRNA vaccines, CRISPR components, polymer-intensive manufacturing systems, and volatile organic contaminants—the analytical burden has grown dramatically. Meeting that burden requires not only ever more sophisticated mass spectrometers but also new chromatographic strategies, improved workflows, and, increasingly, real-time instrumentation.

Interviews with leading experts—Josh McBee, PhD, mass spectrometry scientist lead at Advanced Materials Technology; Xiaoran Zhang, PhD, a senior scientist at Cytiva; Tucker Kitchengs, MBA, a field applications scientist at Syft Technologies; and Bill Farrell and Don Nguyen, PhD, senior scientists at Virscidian—reveal an industry rapidly evolving to keep pace with the complexity of modern therapeutics.

Peptides, RNAs, and a new landscape

For McBee of Advanced Materials Technology, the past several years in pharmaceutical science seem transformative. “I feel like we’re coming into another sort of golden age of pharmaceuticals,” he says, pointing to the explosion in new therapeutic modalities: GLP-1 peptide drugs, siRNAs, antisense RNA, and mRNA vaccines.

This diversification, however, has created unprecedented analytical challenges. Peptides and RNA degrade rapidly in vivo, forcing chemists to introduce modifications that improve stability—but also generate numerous synthetic by-products. These impurities must be rigorously separated and characterized. Regulatory expectations are stringent: “You can have an impurity up to 0.5 percent in the final product, but anything down to 0.1 percent you need to characterize and understand,” McBee notes.

Achieving that kind of characterization requires exceptional chromatographic resolution and high-resolution MS. Yet, even state-of-the-art systems struggle with the newest therapeutics. Oligonucleotides—particularly RNAs, such as siRNAs and longer CRISPR guide RNAs—now entering development, are extraordinarily challenging to separate. “Separating oligonucleotides chromatographically is an order of magnitude more difficult than protein and peptide separations,” he says.

McBee’s team at Advanced Materials Technology develops superficially porous silica particles that improve resolving power without the extreme back pressures associated with ever-smaller particle sizes. Still, data management for mass spec has become its own barrier. With large high-resolution datasets, “the bigger the data sets you collect, the harder it is to maintain your data integrity,” he says, referencing heavy compliance requirements such as 21 CFR Part 11.

As a result, manufacturers are cautious about introducing high-resolution MS into regulated production environments. Instead, simpler triple-quad and single-quad systems are increasingly used for automated in-process control, where known impurities must be quantified reliably and quickly.

McBee remains optimistic about future advances—particularly multidimensional separations and ion mobility—and about the broader therapeutic innovations they will support. “The chemistry is fascinating,” he adds. “I’m very excited about the next 10 or 20 years of drug development.”

Extractables and leachables

While McBee’s work focuses on characterizing therapeutics, Zhang at Cytiva confronts challenges originating not from the drug but from everything surrounding it. Extractables and leachables (E&L) are compounds that migrate from manufacturing materials into drug products, including polymers, stabilizers, and degradation by-products from single-use systems.

“They matter because they directly impact patient safety and product quality,” Zhang explains. Failure to characterize E&L contaminants can compromise the efficiency of a biologic, reduce its shelf life, or introduce toxic substances. But identification is extremely difficult. Manufacturing materials generate complex arrays of oligomers and additives, many lacking reference spectra and exhibiting unpredictable fragmentation.

Zhang observed a group of BADGE (bisphenol a diglycidyl ether)-related compounds in a sample set. Identification remains challenging for many derivatives of BADGE because of the structural diversity and lack of a reference library. “High-resolution MS is critical in these cases, as distinctive chlorine isotopic patterns allow confirmation of the number of chlorine atoms and validation of elemental composition,” Zhang says.

Sample preparation adds another layer of complexity. Protein-rich matrices such as formulated biologics require precipitation, liquid-liquid extraction, or specialized reconstitution steps. Recoveries may falter for highly nonpolar or chemically unstable compounds. “Recovery can be problematic for compounds with unique properties,” Zhang says.

To overcome these obstacles, her group developed targeted liquid chromatography (LC)-QToF (quadrupole time-of-flight) workflows using MSe acquisition, which simultaneously collects low- and high-energy fragmentation data. By identifying diagnostic fragments for nylon and polyethylene-terephthalate oligomers, they were able to rapidly classify unknown peaks through extracted ion chromatograms—sidestepping the need for external spectral libraries. Zhang reports that the approach “significantly reduced identification time and improved confidence in structural assignment.”

She applied a similar strategy to hindered amine light stabilizers, such as Tinuvin 622, extracting fragments from HTPE (4-hydroxy-2,2,6,6-tetramethylpiperidine-1-ethanol) derivatives and incorporating them into an internally curated E&L spectral library. Such databases, Zhang believes, are essential to the future. “I hope we can have a more comprehensive E&L LC-MS database with spectra from various labs,” she says, adding that artificial intelligence–driven processing could accelerate unknown identification and quantitation.

Real-time MS for volatile compounds

While traditional LC-MS instrumentation demands careful chromatography and sample preparation, Kitchengs at Syft Technologies specializes in a radically different analytical philosophy: selected ion flow tube-MS (SIFT-MS). This technique analyzes volatile compounds in real time, without chromatographic separation.

“SIFT-MS provides scientists with a high-throughput, chromatography-free solution for volatile compounds,” Kitchengs explains. The instrument can switch between methods instantly and be operated with minimal training—particularly appealing for manufacturing environments where fast decisions are needed.

[Syft Technologies]

The biggest advantage of SIFT-MS is speed. Residual-solvent analysis, nitrosamine testing, and monitoring of other volatile organic impurities—historically slow, labor-intensive workflows—can be analyzed in seconds instead of minutes or hours. The platform is also sensitive and robust enough to analyze trace contaminants in aqueous solutions, reducing solvent usage in the lab.

Still, SIFT-MS requires users to think differently. Analysts accustomed to chromatography must embrace ion-molecule reaction chemistry instead of retention times and column selectivity. “There is an understandable apprehension to have to learn and apply ion-molecule chemistry,” Kitchengs says. To ease the transition, Syft provides extensive libraries cataloging reaction kinetics for hundreds of compounds.

[Syft Technologies]

Recent advances have expanded SIFT-MS into regulatory spaces. Syft’s Tracer Pharm11 is the first 21 CFR Part 11-compliant real-time mass spectrometer designed for nitrite, nitrosamine, and residual-solvent testing. The goal is to translate established headspace gas chromatography (GC)-MS methods into high-throughput SIFT-MS workflows. Syft Technologies has published extensive data on nitrosamines and residual-solvent analysis, and now looks to extend the technique to nitrite analysis. “Early results for nitrite testing have shown the speed and sensitivity SIFT-MS is known for, with sample results in as little as two minutes.”

A powerful but underused tool

If SIFT-MS represents analytical minimalism, supercritical fluid chromatography (SFC) represents maximum tunability. Farrell and Nguyen of Virscidian describe SFC as a highly selective, versatile technique that complements traditional HPLC while offering capabilities difficult to achieve otherwise.

SFC relies on supercritical CO₂ combined with small amounts of organic modifiers, enabling interactions that blend characteristics of normal-phase, reverse-phase, and entirely unique separation mechanisms. Farrell summarizes: “It has a bit of a crossover between the two.”

SFC’s strength lies in its mechanistic diversity. While high-performance LC (HPLC) separations depend largely on partitioning and pH control, SFC enables dipole, hydrogen-bonding, acid–base, and other interactions. Such flexibility can produce separations that HPLC struggles with—if the analyst understands the system. “You can have the wrong stationary phase but the right solvent and the peak never comes out, or the right stationary phase and the wrong solvent,” Farrell notes. This dual dependence makes SFC powerful but complex.

Nguyen highlights one of SFC’s most important applications: chiral separations. Pharmaceuticals often require enantiomerically pure compounds, and the consequences of contamination can be severe. Fragile polysaccharide chiral columns degrade in many organic solvents but remain stable in CO₂. The wrong enantiomer in a drug can be disastrous, Nguyen points out, and that’s one reason SFC remains indispensable in discovery chemistry.

Coupling SFC to MS introduces additional challenges. The decompression of supercritical CO₂ generates massive gas volumes, making electrospray ionization difficult without additives. Farrell favors atmospheric pressure chemical ionization (APCI) because it “handles the flow rate the best,” he says, and works well across diverse molecular classes.

SFC also provides sustainability benefits. When purification fractions are collected, CO₂ evaporates immediately, leaving minimal solvent to remove. This reduces energy consumption and avoids the difficulties of desolvating water-heavy samples.

Finally, SFC’s unusual environment—low polarity, minimal water—can reveal physicochemical properties invisible in conventional solvents. Intramolecular hydrogen bonding becomes more pronounced, influencing retention and providing insights into permeability. Farrell notes that these effects have been “used pretty perfectly at a bunch of different companies” for predicting passive diffusion in early drug development.

A future of complementary tech

Taken together, these interviews describe a field poised for convergence rather than competition. McBee’s high-resolution peptide and oligo workflows, Zhang’s E&L spectral strategies, Kitchengs’s real-time volatile testing, and Farrell and Nguyen’s tunable SFC-MS separations all address different corners of an increasingly complex biomanufacturing ecosystem.

Mass spectrometry, in its many forms, is not merely keeping pace with biotechnology—it is defining what is analytically possible. As therapeutic architectures grow more sophisticated and manufacturing systems become more elaborate, the industry will continue relying on MS-driven innovation to ensure safety, efficiency, and scientific discovery in what might indeed be a new golden age of pharmaceuticals.

The post Mass Spectrometry’s Expanding Frontier appeared first on GEN – Genetic Engineering and Biotechnology News.