Introduction

Modern materials science has found that when materials are reduced to the nanoscale and their morphologies are altered, their physical and chemical properties can be significantly changed. By carefully controlling the size and shape of nanomaterials, scientists can create materials with specific, desired properties. Traditional chemical methods for producing these nanomaterials are popular because they enable precise control over the size and shape of the particles. However, these methods often require surfactants or capping agents-chemicals that help control the growth of the nanomaterials. Unfortunately, these chemicals can remain on the surface of the nanomaterials after the reaction, blocking important active sites and reducing the effectiveness of the nanomaterials in certain applications. Due to this issue, there is a need for new methods of synthesizing nanomaterials that do not require surfactants or capping agents, thereby enabling the production of nanomaterials with the desired properties in a cleaner and more efficient manner.

Microbial synthesis is an eco-friendly method to produce pure nanomaterials. In this process, microorganisms such as bacteria are utilized to produce nanostructured materials. These microorganisms interact with metal ions to form nanoparticles. Once the bacteria have completed their life cycle, they naturally detach from the nanostructures or can be removed by simple treatments, such as applying thermal shock, leaving behind pure nanomaterials. However, the biosynthesis process can sometimes be complex due to the various chemical reactions within bacterial cells, which affect the productivity of the method1. Nanoparticles of several metals, such as gold (Au), silver (Ag), platinum (Pt), palladium (Pd), titanium (Ti), and magnetites, as well as metal oxides like titanium dioxide (TiO2) and zinc oxide (ZnO), were successfully synthesized using the biosynthesis process2. Producing nanoparticles with heavy metals can be challenging because of their toxicity. Some bacteria have developed ways to protect themselves from this toxicity by reducing metal ions and forming water-insoluble complexes, which lead to the formation of metal nanoparticles2 or metal chalcogenide nanoparticles like zinc sulfide (ZnS)3, cadmium sulfide (CdS)4,5, and lead sulfide (PbS)6,8. This bacterium is found in various environments, such as air, freshwater, soil, and even on the skin of mammals9.

The Micrococcus luteus bacterium was successfully used for the synthesis of Ag and Au nanoparticles. Patel et al.10 synthesized Ag nanoparticles using the Micrococcus luteus bacterium for methyl orange (MO) dye degradation. Arunkumar et al.11 reported the synthesis of Au nanoparticles using the Micrococcus luteus bacterium. Some bacteria, like Lysinibacillus sphaericus and Pseudomonas aeruginosa, can produce lead sulfide (PbS) nanoparticles. It happens through enzymatic reactions, where the bacteria convert lead ions (Pb²⁺) into PbS by reacting them with sulfur-containing compounds. This biological method is a simple and eco-friendly approach for synthesizing PbS nanoparticles12,13. Recent studies have demonstrated that bacteria, such as Lysinibacillus sp., can produce zinc sulfide (ZnS) nanoparticles through the desulfurization of L-cysteine14. In this process, the bacteria break down L-cysteine, releasing sulfur, which then reacts with Zn ions to form ZnS nanoparticles. To the best of our knowledge, there are no reports that exist in the literature documenting the use of Micrococcus luteus for the biosynthesis of PbS nanoparticles. The novelty of using Micrococcus luteus lies in its unique metabolic pathways and surface biomolecules, which contribute to the controlled nucleation and growth of PbS nanoparticles under mild conditions, eliminating the need for external capping or stabilizing agents. It results in the nanoparticle’s distinct morphological and optical properties compared to those synthesized using previously reported microbes. Due to its high tolerance to metal ions and lack of pathogenicity, Micrococcus luteus is considered safe to handle in most laboratory environments. Its capacity to produce enzymes enables extracellular reduction, making purification and scaling up easier. Its spherical shape facilitates the monitoring of cultures and contamination. With this motivation, we aimed to explore the synthesis of PbS nanoparticles using the bacterium Micrococcus luteus. In the present work, we report the synthesis of spherical-shaped lead sulfide (PbS) nanoparticles by growing Micrococcus luteus in a lead-toxic environment. Before the synthesis, we carefully studied factors such as solution pH, solution concentration, and reaction time (or culture time) that affected the bacterial life cycle. We then performed PbS synthesis under different conditions by varying the solution concentrations and toxicity levels and recorded the bacterial growth over various reaction times. Finally, the synthesized PbS nanoparticles were successfully used to fabricate photodetectors, demonstrating the potential of Micrococcus luteus in nanomaterial applications.

Experimental details

Organism and cultivation

Micrococcus luteus is harmless and habitually found in air, water, and dust, and it colonizes human skin. Considering air and dust as the primary sources15, the samples were collected through the air by exposing nutrient agar culture plates to an open atmosphere at ambient conditions. The culture plates containing the collected samples were transferred to a sterile incubator at 37 °C for various incubation times, and the growth of bacterial colonies was recorded. The pure bacterial colony was isolated and spread onto a sterile agar plate using a loop. These plates were again transferred to an incubator at 37 °C for 24 to 48 h. Figure 1a and b show photographs of culture plates describing isolated bacterial colonies after incubation using the streak plate technique.

Photographs of culture growth: a, b isolated bacterial colonies during incubation marked by an arrow, sub-culture growth c on the nutrient agar plates, and d in the nutrient broth.

Yellow-colored colonies of microorganisms were transferred and spread to new plates. These sub-cultured plates were then incubated at 37 °C for 24–48 h, as shown in Fig. 1c. This process is similar to the method used by Qayyum et al.16, who also purified pigment-producing bacteria using the streak plate technique on nutrient agar. The sub-cultured grew well in the broth nutrient medium, as shown in Fig. 1d. Photographs of cultural media and plates are provided in Supplementary Information (Figs. S1 and S2). Based on the results obtained from the biochemical examination, the selected bacterial colony was identified as Micrococcus luteus. Morphological and biochemical tests were performed to identify isolated bacteria. Morphological characterization of bacteria was done by observing the samples under an optical microscope to reveal the physical appearance of bacterial colonies grown on an agar plate. We observed that the obtained spherical colonies were mainly in pairs, tetrads, and irregular bunches and appeared yellow. The measured cell diameter was found to be between 0.5 and 2.0 μm. Bacteria were non-motile and had an aerobic type of cellular respiration.

A catalase test was performed on the selected bacterial colonies. When a drop of hydrogen peroxide (H2O2) was poured on the bacteria, bubbles formed due to the enzyme catalase’s catalytic activity, indicating the breakdown of H2O2 into oxygen and water, which confirms that the bacteria are catalase-positive. The photographs of the catalyze test are given in Fig. S3 of the Supplementary Information. Gram staining tests were performed on the colonies. We found higher peptidoglycan and lower lipid content, confirming that the bacteria are Gram-positive microorganisms. Optical microscopic images of the Gram-stained samples are provided in the Supplementary Information (Fig. S4). An oxidase test was also performed on the colonies, and photographs of the oxidase test results are provided as Supplementary Information (Fig. S5). A positive response was observed within 5–10 s, indicated by a purple tone, confirming the presence of cytochrome c oxidase. These Morphological and biochemical tests identified and confirmed that the cultured bacteria were Micrococcus luteus.

Optimization of pH value

To optimize the pH level for the efficient growth of Micrococcus luteus bacteria, we prepared a series of nutrient broth flasks with different pH values ranging from 6 to 11. We adjusted the pH of the broth by adding either hydrochloric acid (HCl) to make it more acidic or sodium hydroxide (NaOH) to make it more basic until we reached the desired pH levels. We also prepared reference flasks with a neutral pH for comparison. Next, we added 5–10 colonies of Micrococcus luteus bacteria to each flask and incubated them at 37 °C for 24–48 h to allow the bacteria to grow. To measure bacterial growth, we observed the turbidity of the broth. We then used a colorimeter to measure the optical density (OD) at 630 nm, providing a more precise measure of bacterial growth. The data collected will be plotted on a graph to determine the optimal pH range for the growth of Micrococcus luteus bacteria, which will be discussed later in the results and discussion section.

Microbial synthesis of PbS nanoparticles

Lead nitrate [Pb(NO3)2] solutions with different concentrations (0.01 M, 0.005 M, and 0.0025 M) were prepared in different containers. These solutions were then added to the nutrient broth solutions in a conical flask. These solutions are then heated to ensure that the solution is completely dissolved. These flasks were then inoculated with 5–10 colonies of Micrococcus bacteria and incubated at 37 °C for various inoculation times, viz., 24, 48, 72, and 96 h. After incubation, the precipitate was placed in the deep freezer for 10 min and then immediately transferred to an 80 °C water bath for an additional 10 min. After thermal shock treatment, the sample was centrifuged at 5000 rpm for 10 min to separate the obtained product. The obtained product was then washed several times with distilled water by using centrifugation and separation methods. After washing, the samples were transferred to a clean and dry petri dish and then dried in a vacuum oven for several hours at 120 °C. A similar procedure was repeated for incubation times of 48–96 h with Micrococcus bacteria. As the incubation time increased, the powder became darker in color, indicating an increase in PbS formation. The powder was collected at different concentrations and at time intervals ranging from 24 to 96 h. The color of the powder changes from brown to dark brown for 0.01 M concentration of lead nitrate and nutrient broth. At a 0.0025 M concentration of lead nitrate and nutrient broth, the color changes from grey to dark grey or black, indicating the formation of PbS. The obtained powder was then stored in a centrifuge tube for further processing. The obtained powder was stored in a centrifuge tube for further processing.

Figure 2 shows the step-by-step process of synthesizing PbS nanoparticles using microbial methods. The first step involves the growth of Micrococcus luteus bacteria, which appeared in yellow, spherical colonies, as illustrated in Fig. 2a. We prepared a medium with a pH of 7 to cultivate these bacteria. The highest optical density was observed with the medium with a pH of 7, suggesting that a pH of 7 is optimal for the growth of Micrococcus luteus. This finding is consistent with research by Benjamin et al.17, which demonstrated that efficient pigment production occurs in Micrococcus luteus when grown in a nutrient broth at a pH of 7. Another study also confirmed that most pigments were produced at this pH level18. Micrococcus luteus typically requires low oxygen levels, between 1% and 10%, making it an obligate aerobe. It is also a gram-positive bacterium, meaning it has thicker cell walls. A preliminary catalase biochemical test (discussed later) confirmed that the cultured Micrococcus luteus bacteria produce catalase. In this reaction, catalase helps break down nitrate anions into oxygen and nitrogen. The bacteria use oxygen for respiration, while the nitrogen produces important components, such as amino acids, essential for their metabolic activities19,20. In this process, we used Pb(NO3)2 as the source of Pb. When lead nitrate is added to the culture medium, it breaks down into Pb+ ions and nitrate anions. The catalase enzyme, present in the bacteria, helps break down nitrate anions, as shown in Fig. 2b.

Schematic representation of the reaction mechanism of PbS nanoparticles synthesis a before mixing, b after mixing, c reaction time, and d final PbS nanoparticles.

Catalase is an antioxidant enzyme that protects bacteria from damage caused by reactive oxygen species in polar solvents and air21. The culture medium contains nutrient broth, which acts as a food source for the bacteria and provides sulfur. Nutrient broth consists of peptone, agar, and either beef or yeast extract. Peptone, in particular, provides amino acids, sulfur, and other essential elements. The sulfur from peptone serves as a source of elemental sulfur during the reaction. It has also been observed that some bacteria produce hydrogen sulfide (H2S) by breaking down sulfur-containing amino acids to meet their energy needs. In the present case, H2S gas was released by breaking down peptone molecules. When H2S gas reacted with the Pb+ ions, spherical PbS nanoparticles were formed, as shown in Fig. 2c and d. This process depends on the rate at which H2S gas and Pb+ ions are released, which determines the final properties of the PbS nanoparticles. To better understand and control this process, we adjusted the concentration of Pb+ ions and varied the reaction time.

Fabrication of TiO2 thin film, polyaniline (PANI), and NiS powder

The electron transport layer (ETL) of mesoporous TiO2 was deposited using the spin coating method, followed by cleaning the 1.5 × 1.5 cm2 FTO-coated glass substrates. A solution of 1.1 g of TiO2 powder was prepared in 8.5 mL of ethanol, and then 1.5 mL of acetylacetone was added to the mixture. Then, this solution was subjected to 30 min of ultrasonication. In a typical deposition, a 200 µL TiO2 solution was spread over the substrate and spin-cast at 4000 rpm for 45 s. This film was then thermally treated in a muffle furnace at 500 °C for 45 min. The result was obtained in ∼ 500 nm thick and super adherent mesoporous TiO2 layer.

To prepare the polyaniline (PANI), which acts as the hole-transporting layer (HTL), we first prepared 100 mL of a 1 M HCl solution using double-distilled water. Then, half of this stock solution (50 mL) was kept in an ice bath to maintain a temperature of 0 °C. Then, 5 g of ammonium persulfate [(NH4)2S2O8] was added with continuous stirring. In the other half of the stock solution, 2 mL of aniline solution was added, with continued stirring, at 0 °C in an ice bath. The solution containing ammonium persulfate was then added gradually to the second aniline solution. After 30 min of total mixing, the obtained product was filtered and washed once with a 1 M HCl solution, followed by three washes with double-distilled water. The green-colored precipitate of PANI was then stored by drying at 60 °C in a vacuum oven for 6 h.

A simple chemical route is used to synthesize powder of the second hole-transporting layer of NiS. A solution of 0.1 M nickel nitrate [Ni(NO3)2] was prepared in 50 mL double-distilled water, then ∼ 9 mL ammonia solution was sluggishly added into it to adjust the pH value to 9–10 with continued stirring for 10 min. A precipitate of nickel hydroxide complex forms. Then, in another beaker, a solution of 0.1 M Na2S·H2O was prepared in 50 mL of double-distilled water and was stirred. This second solution was added dropwise to a previously prepared solution, stirred vigorously, and maintained at room temperature for 30 min. The solution rapidly goes black, demonstrating the formation of NiS. The obtained NiS product was purified using a centrifugation and separation method with water and methanol three times at 4500 rpm for 7 min. Then, NiS powder was stored and dried at 120 °C in a vacuum oven.

Device fabrication

The epitaxial multilayer stacked-type device was prepped using the spin coating on mesoporous TiO2-coated FTO/Glass substrates. Typically, a 50 mg/mL ethanoic solution of synthesized PbS was cast over a mesoporous TiO2 layer at 1500 rpm for 45 s. Then, 200 mg/mL of PANI + DMF solution was spin-coated at 2000 rpm for 60 s to obtain the PANI layer. The second hole-transporting NiS layer was developed by depositing 100 mg/mL ethanolic solution of NiS by spin coating at 2000 rpm for 60 s. The third hole-transporting layer of V2O5 was deposited by casting 100 µL of 50 mg/mL ethanolic solution of commercially available V2O5 powder at 2000 rpm for 45 s. The device was immediately annealed at 120 °C on the hot plate for 10 min.

Characterization techniques

A Shimadzu UV-1800 spectrophotometer was used to record UV–visible absorption spectra to determine the band gap of the synthesized nanostructures. A Bruker D8 X-ray diffractometer was used to obtain X-ray diffraction patterns to study the crystal structure of synthesized PbS nanoparticles. Optical microscopic images were obtained using the Olympus DP70 digital camera system to identify the morphology of the bacterial colonies. SEM images were obtained using a JEOL JSM630A scanning electron microscope to determine the particle’s mean size. EDX spectra were obtained using a Bruker XFlash 6I30 EDX detector. The performance of the fabricated photodetector device was measured using a Keithley 2450 source meter under white light illumination, using A Class ABA Solar Simulator, ORIEL Sol 2A 94,022 A, having an intensity of 100 mW/cm2.

Results and discussion

Effects of pH on the growth of micrococcus bacteria

It was expected that the variation in pH values would alter the growth rate of the bacteria. To identify and quantify the growth rate at different pH values, a series of nutrient broth conical flasks was prepared with varying pH values ranging from 6 to 11. The pH values were adjusted by adding a specific amount of hydrochloric acid (HCl) or sodium hydroxide (NaOH) to the nutrient broth culture medium. Control (or reference) solutions with a neutral pH were also prepared in conical flasks for comparative investigations. Then, the prepared conical flasks were inoculated with 10 colonies of Micrococcus bacteria and incubated at 37 °C for 24–48 h for further growth. The growth of the bacteria was determined by observing the turbidity of the broth culture, which indicates the amount of bacterial growth. The growth of the bacteria was analyzed using the standard method, measuring the optical density (OD) at 630 nm with a colorimeter18. Then, each sample’s approximate cell density in CFU/mL (colony-forming unit per milliliter) at different pH values was computed by comparing the recorded data with the McFarland standards table. The variation in optical density, in relation to pH value and time duration, is noted and tabulated in Table 1. Then, to reveal the optimal pH range for the growth of the Micrococcus bacteria, the relative graphs of optical density versus pH values and optical density versus time were plotted and shown in Fig. 3a and b, respectively.

After incubating every 24 h, the growth of the bacteria in each conical flask was monitored. It was found that the growth of the bacteria after 24 h is higher for a pH of 9. After 48 h, there was an increase in optical density for 7 and 8 pH values. However, at a pH of 6, there was negligibly small bacterial growth.

These results indicate that neutral to alkaline pH favors optimum growth. However, after an incubation time of 48 h, the maximum optical density was observed for a pH of 8. Then, after an incubation time of 72 h, the bacterial growth was saturated for a pH of 7. This saturation condition was assumed to be ideal for the synthesis. Hence, for the culture, a pH of 7 and an incubation time of 72 h were ideal for synthesizing PbS nanoparticles using Micrococcus bacteria. Visual observation suggested that the maximum PbS nanoparticle production is obtained after more than 72 h of incubation at a culture pH of 7.

Properties of PbS nanoparticles

The optical properties of PbS nanoparticles, such as optical absorption and band gap, were determined using UV–visible spectroscopy. Figure 4a shows the optical absorption spectrum of PbS nanoparticles synthesized with different solution concentrations at 72 h of culture incubation at a pH of 7. It is observed from the figure that the absorption edge of PbS nanoparticles is at ∼ 425–450 nm without apparent absorption in the UV region. The PbS nanoparticles prepared with a 0.0025 M concentration show higher absorbance values. It covers the entire visible light region, indicating that the PbS nanoparticles have a high optical absorption coefficient in the visible region.

Figure 4b represents the variation of the optical band of PbS nanoparticles synthesized with different solution concentrations at 72 h of culture incubation using Tauc’s plots. The absorption coefficient (α) of the material is calculated using,

$$alpha =2.303 times frac{{{text{~A}}}}{{text{t}}}$$

(1)

The optical band gap was calculated by using the absorption coefficient using the relation22,

$${{hvarvec{upnu}}}={text{A}}{left( {{text{h}}vartheta – {{text{E}}_{text{g}}}} right)^{text{n}}}$$

(2)

Where hν is the incident light energy in eV, Eg is the band gap energy in eV, and A is the constant. The value of n depends on the specific optical transition occurring in the material. It takes the value 2 for an indirect allowed transition, while 3 for an indirect forbidden transition. The band gap energy can be determined by inferring the tangent to the X-axis in the graph of (αhυ)2 as a function of energy (hυ). It was observed that as the solution concentration increases, the band gap value also increases. The increase in band gap with increasing solution concentration may be attributed to a decrease in particle size of the synthesized PbS nanoparticles. Due to its toxic nature, a higher concentration of lead nitrate may reduce the number of bacteria. As a result, there will be a reduction of H2S production, causing slower nucleation and growth of PbS molecules and consequently decreasing the particle size of PbS.

a UV–visible absorbance spectrum, and b band gap of PbS nanoparticles synthesized with different solution concentrations at 72 h of culture incubation.

At the nanoscale, bandgap shifting is typically strongly influenced by the particle size of nanostructures. Therefore, the synthesized PbS powders were also examined using the XRD characteristic technique to evaluate crystallite size and confirm stoichiometric phase purity. The obtained XRD pattern of the PbS powder synthesized at different solution concentrations for 72 h is shown in Fig. 5. Diffraction peaks at 2θ ∼ 27.4°, 20.6°, 41.9°, 59.5°, and 60.8° are observed, which originate from (111), (200), (220), (222), and (400) planes, respectively. The peaks of these samples were matched with the standard data from JCPDS Card # 05-059223, indicating the cubic PbS phase. No additional peak was found, confirming the formation of the pure phase of PbS. However, the broadening of the XRD diffracted peaks was also observed due to the formation of nano-sized PbS nanoparticles. The highest intensity of the peak shows that the grains are preferentially oriented along the (200) direction.

The crystallite size was calculated by using Debye–Scherrer’s equations24,

$${text{D}}=frac{{{{{text{k}}varvec{uplambda}}}}}{{{{varvec{upbeta}~cos~varvec{uptheta}}}}}$$

(3)

Where k is the wavelength of incident x-ray source radiation (Cukα = 1.54 Å), k is the particle shape factor and taken as 0.9, β is the full width at half maximum (FWHM), and θ denotes Bragg’s diffraction angle. The calculated average crystallite sizes for all samples are listed in Table 2. The interplanar spacing (d200) of the PbS nanoparticles is estimated using Bragg’s equation,

$${{text{d}}_{200}}= frac{{{{{text{n}}~varvec{uplambda}}}}}{{2{text{~Sin}}(theta )}}$$

(4)

The calculated value of interplanar spacing of the PbS nanoparticles is ∼ 0.2924 nm, in accordance with recently reported results25.

Being a cubic structure, the lattice constants (a = b = c) of PbS were calculated using26,

$${text{a}}= {{text{d}}_{{text{hkl}}}}sqrt {{h^2}+{k^2}+{l^2}}$$

(5)

Where h, k, and l are the Miller indices, and dhkl is the interplanar distance.

Interestingly, we observed that all samples possess the same average lattice constant value of ∼ 0.5848 nm, indicating no shift in the cubic crystallographic phase and no modification in crystal structure upon change in molar concentration.

Dislocation density (δ) measures how many irregularities or dislocations are present in a crystal structure. It is calculated by taking the ratio of the length of dislocation lines and the volume of the crystal27,

$$delta =frac{{text{n}}}{{{text{D}}_{{{text{hkl}}}}^{2}}}$$

(6)

The estimated values of band gap, Urbach energy, crystallite size, interplaner distance, lattice parameters, and dislocation density of PbS nanoparticles synthesized in different solution concentrations are listed in Table 2. Comparative investigations from Table 2 reveal that, as the solution concentration increases, the crystallite size decreases due to a reduction in the number of bacteria in the solution, increasing the optical band gap.

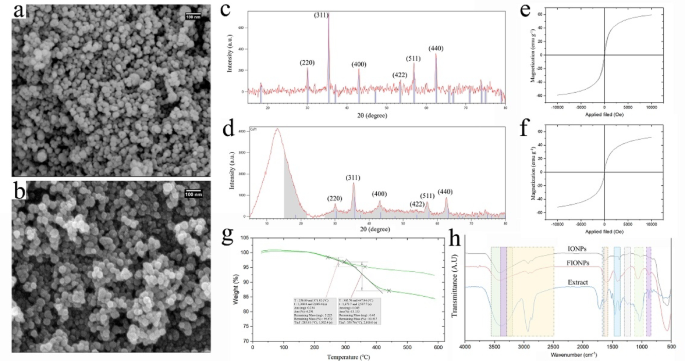

Dimensional and morphological properties of the synthesized PbS powder have also been examined using scanning electron microscopy (SEM). Figure 6a1–a3 show SEM images captured for the PbS powder synthesized with different solution concentrations. The SEM images confirm the formation of spherical-shaped PbS nanoparticles. The average particle size was determined by analyzing the SEM images using ImageJ software, and the diameters of the PbS nanoparticles obtained were in the range of 150–250 nm.

a1–a3 Scanning electron microscopic images and b1–b3 energy-dispersive X-ray spectrum of PbS nanoparticles synthesized in different solution concentrations.

Additionally, during SEM characterization, the EDX spectra were also evaluated for the samples under consideration. The obtained EDAX spectra of the PbS samples prepared with different solution concentrations are shown in Fig. 6b1–b3. We found a ∼ 1:1 atomic ratio of Pb and S, confirming the formation of pure PbS phase. These results support the analogy of the XRD stoichiometric analysis. FTIR spectra obtained for the synthesized PbS with a cultured solution concentration of 0.0025 M confirm the formation of the PbS phase. Figure S6 in the Supplementary Information provides further support for it.

Analyzing the overall results obtained from the characterization techniques, we found that PbS prepared with a 0.0025 M solution concentration is ideal for optoelectronic applications. Therefore, these synthesized PbS nanoparticles were employed to fabricate photodetection devices. The photodetector device is fabricated using a specific design illustrated in Fig. 7a. Figure 7b provides a schematic representation of the energy levels in the device. In this structure, TiO2 collects the electrons generated by light and then passes them to the electrode. On the other hand, PANI, NiS, and V2O5 capture the holes (which are positive charge carriers) and transfer them to the platinum back contact.

In fabricated devices, synthesized PbS is important as a light harvester. The harvested light reveals a significant change in the static I–V characteristics of the device, as obtained in the voltage range of − 1 to 1 V with and without light illumination, as shown in Fig. 8a. The increase in current when exposed to the light confirms that the PbS layer acts as a photoactive semiconductor. In considering photodetector applications, the photoconduction mode is particularly important. Figure 8b shows the transient kinetic current versus time (I–t) characteristics plot for the microbial PbS-based photodetector device. The photodetector exhibits a constant current over the cycles, indicating good stability and repeatability. For a photodetector device, the rise time (τRise) is defined as the time it takes from its dark current to 90% of its maximum current when exposed to light. The fall time (τFall) is defined as the time it takes to drop from its light-exposed current back down to 10% of its dark current value28. The rise and fall times of the microbial PbS-based photodetector were calculated using a single photoresponse cycle. Figure 8c shows a typical single-cycle I–t curve of the microbial PbS-based photodetector.

a Static IV characteristics with and without light illumination conditions, and b Transient IV characteristics of photodetector device up to 10 cycles. c Transient IV characteristics of single cycles to determine rise and fall time.

The rise and decay processes follow an exponential law,

$${text{I}}={{text{I}}_{0}}{{text{e}}^{frac{{ – {text{t}}}}{{{{text{varvec{uptau}}}_{{text{Rise}}}}}}}}$$

(7)

$${text{I}}={{text{I}}_{0}}{{text{e}}^{frac{{ – {text{t}}}}{{{{text{varvec{uptau}}}_{{text{Fall}}}}}}}}$$

(8)

Where I0 is the photocurrent, τRise and τFall are the rise and fall times, respectively, and t is the time constant. The measured rise time of 0.940 s and fall time of 0.478 s promise a fast-switching application for microbial PbS-based photodetectors.

The performance of the microbial PbS-based photodetector fabricated at 0.0025 M solution concentration was further explored by calculating its photoresponsivity (R), photosensitivity (ξ), and detectivity (D*) parameters. The photoresponsivity is the photocurrent generated per unit incident of light power density on the device and is given by29,

$${{text{R}}_lambda }=frac{{Delta {text{I}}}}{{{{text{P}}_{{text{in}}}}{text{~S}}}}$$

(9)

Where ΔI = Iphoto−Idark is the change in photocurrent due to incident light, Pin is the intensity of incident light, and S is the active area of the photodetector. The calculated value of photoresponsivity for the microbial PbS-based photodetector fabricated at 0.0025 M solution concentration is ∼ 0.56 µA/W.

The photosensitivity (ξ) of a photodetector is defined as the ratio of relative change in current to the dark current and is given by30,

$${text{varvec{upxi}}}=frac{{{{text{I}}_{{text{photo}}}} – {{text{I}}_{{text{dark}}}}}}{{{{text{I}}_{{text{dark}}}}}}$$

(10)

The calculated value of photoresponsivity for the microbial PbS-based photodetector fabricated at 0.0025 M solution concentration is 1.10.

The photodetection quality of a photodetector is measured in terms of detectivity (D*). It is measured in Jones and expressed as31,32,

$${{text{D}}^{text{*}}}=frac{{{{text{R}}_lambda }}}{{sqrt {2{text{q~}} times {{text{J}}_{{text{Dark}}}}} }}$$

(11)

Where JDark denotes the dark current density. In the present study, the noise-limiting detectivity of the microbial PbS-based photodetector is ∼ 30.9 × 107 Jones at − 1.0 V bias voltage.

Table 3 summarizes the rise time, fall time, and detectivity of PbS photodetectors fabricated using various methods. The data obtained in the present work are also included in the table.

The fabricated FTO/TiO2/PbS/PANI/NiS/V2O5/Pt photodetector shows lower performance compared to similar devices reported in the literature. We believe that improving the fabrication conditions of the device could lead to better performance. However, it is noteworthy that this study successfully demonstrated the microbial synthesis of PbS nanoparticles using Micrococcus luteus bacteria, showing their potential for use in photodetector applications.

In conclusion, the study successfully demonstrated the extracellular synthesis of lead sulfide (PbS) nanoparticles using Micrococcus luteus bacteria under optimized conditions. The results showed that the PbS nanoparticles, with sizes ranging from 150 to 250 nm, were pure and spherical, as confirmed by XRD and SEM analyses. The FTIR spectra further verified the purity of the PbS phase. The optoelectronic properties of the PbS nanoparticles, evaluated using UV–visible absorption spectroscopy, revealed strong optical absorption in the NIR region, making PbS suitable for optoelectronic applications. Additionally, it was observed that the band gap increased with higher solution concentration. The fabricated photodetector device, utilizing the FTO/TiO2/PbS/PANI/NiS/V2O5/Pt architecture, exhibited excellent stability, repeatability, and fast switching capabilities, with rise and fall times of 0.94 s and 0.478 s, respectively. The high photodetectivity (30.9 × 107 Jones) indicates its potential for fast-switching applications. These findings suggest that the synthesized PbS nanoparticles and the fabricated photodetector device have promising prospects in optoelectronics.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author upon reasonable request.

References

-

Li, S., Li, Y. & Smolke, C. D. Strategies for microbial synthesis of high-value phytochemicals. Nat. Chem. 10, 395–404. https://doi.org/10.1038/s41557-018-0013-z (2018).

-

Iravani, S. & Prospects Bacteria in Nanoparticle Synthesis: Current Status and Future International Sch. Res. Not. 359316. https://doi.org/10.1155/2014/359316. (2014).

-

Bai, H. J., Zhang, Z. M. & Gon, J. Biological synthesis of semiconductor zinc sulfide nanoparticles by immobilized Rhodobacter sphaeroides. Biotechnol. Lett. 28, 1135–1139. https://doi.org/10.1007/s10529-006-9063-1 (2006).

-

Holmes, J. D. et al. Cadmium-specific formation of metal sulfide Q-particles’ by Klebsiella pneumoniae. Microbiology 143, 2521–2530. https://doi.org/10.1099/00221287-143-8-2521 (1997).

-

Bai, H., Zhang, Z., Guo, Y. & Jia, W. Biological synthesis of size-controlled cadmium sulfide nanoparticles using immobilized Rhodobacter sphaeroides. Nanoscale Res. Lett. 4, 717–723. https://doi.org/10.1007/s11671-009-9303-0 (2009).

-

Bai, H. J. & Zhang Microbial synthesis of semiconductor lead sulfide nanoparticles using immobilized Rhodobacter sphaeroides. Mater. Lett. 63, 764–766. https://doi.org/10.1016/J.MATLET.2008.12.050 (2009).

-

Kowshik, M., Vogel, W., Urban, J., Kulkarni, S. K. & Paknikar, K. M. Microbial synthesis of semiconductor PbS nanocrystallites. Adv. Mater. Commun. 14, 815–818. https://doi.org/10.1002/1521-4095(20020605)14:11<815::AID-ADMA815>3.0.CO;2-K (2002).

-

Madigan, M., & Martinko, J. Brock. Biology of Microorganisms, 11th Edn., Prentice Hall (2005).

-

Betts, G. Other spoilage bacteria. Food spoilage microorganisms, Chap. 23 pp. 668–695, Campden and Chorleywood Food Research Association, UK, (2006). https://doi.org/10.1533/9781845691417.5.668

-

Patel, B. et al. Bacteriogenic synthesis of morphologically diverse silver nanoparticles and their assessment for Methyl orange dye removal and antimicrobial activity. Peer J. 12, e17328. https://doi.org/10.7717/peerj.17328 (2024).

-

Arunkumar, P., Thanalakshmi, M., Kumar, P. & Premkumar, K. Micrococcus luteus mediated dual mode synthesis of gold nanoparticles: involvement of extracellular α-amylase and cell wall teichuronic acid. Colloids Surf. B Biointerfaces. 103, 517–22. https://doi.org/10.1016/j.colsurfb.2012.10.051 (2013).

-

Wei, S., Guo, C., Wang, L., Xu, J. & Dong, H. Bacterial synthesis of PbS nanocrystallites in one-step with l-cysteine serving as both sulfur source and capping ligand. Sci. Rep. 11, 1216. https://doi.org/10.1038/s41598-020-80450-7 (2021).

-

Öcal, N., Ceylan, A. & Duman, F. Intracellular biosynthesis of PbS quantum dots using Pseudomonas aeruginosa ATCC 27853: evaluation of antibacterial effects and DNA cleavage activities. World J. Microbiol. Biotechnol. 36, 147. https://doi.org/10.1007/s11274-020-02917-z (2020).

-

Wei, S. & Zheng, Q. Biosynthesis and characterization of zinc sulphide nanoparticles produced by the bacterium Lysinibacillus sp. SH74. Ceram. Int. 50, 2637–2642. https://doi.org/10.1016/j.ceramint.2023.10.246 (2024).

-

Kooken, J. M., Fox, K. F. & Fox, A. Characterization of Micrococcus strains isolated from indoor air. Mol. Cell Probes. 26, 1. https://doi.org/10.1016/j.mcp.2011.09.003 (2012). e5.

-

Greenblatt, C. L. et al. Micrococcus luteus-survival in amber. Microb. Ecol. 48, 120–127. https://doi.org/10.1007/s00248-003-2016-5 (2004).

-

Qayyum, S. et al. Isolation, identification and antibacterial study of pigmented bacteria. Appl. Nanosci. 10, 4495–4503. https://doi.org/10.1007/s13204-020-01363-5 (2020).

-

Benjamin, S., Pawar, Y. S., Dhanya, P., Sarath, J. M. K. & Pradeep, S. Micrococcus luteus Strain BAA2, a novel isolate produces carotenoid pigment. eJBio 12, 83–89 (2016).

-

Keenleyside, W. & Microbiology Canadian Edition, Chap. 9, Microbial Growth and Biosynthesis, Oxygen Requirements for Microbial Growth, Pressbooks, Toronto (2019).

-

Reitzer, L. J. Ammonia assimilation and the biosynthesis of glutamine, glutamate, asparate, asparagine, l-alanine and d-alanine, 301–407. In (ed Neidhardt, F. C.) Escherichia coli and Salmonella: cellular and molecular biology, 2nd ed. ASM, Washington, DC. (1996).

-

Jeeva, J. S. et al. Enzymatic antioxidants and its role in oral diseases. J Pharm. Bioallied Sci. 7, S331–S333. https://doi.org/10.4103/0975-7406.163438 (2015).

-

Patel, S. L., Chander, S., Purohit, A., Kannan, M. D. & Dhaka, M. S. Influence of NH4Cl treatment on physical properties of CdTe thin films for absorber layer applications. J. Phys. Chem. Solids. 123, 216–222. https://doi.org/10.1016/j.jpcs.2018.07.021 (2018).

-

Mamiyev, Z. Q. & Balayeva, N. O. Preparation and optical studies of PbS nanoparticles. Opt. Mater. 46, 522–525. https://doi.org/10.1016/j.optmat.2015.05.017 (2015).

-

Patterson, A. L. The scherrer formula for X-ray particle size determination. Phys. Rev. 56, 978–982. https://doi.org/10.1103/PhysRev.56.978 (1939).

-

Sultan, A. Facile Preparation of a pbs:ni nanostructure using solid state synthesis route: microstructural, dielectric, and electrical properties. Electrochem. Mater. Technol. 3, 20243033. https://doi.org/10.15826/elmattech.2024.3.033 (2024).

-

Pomar, F. S. E. P. Study of the structural properties of nanostructured PbS thin films deposited by RF sputtering at room temperature. Mater. Res. Express. 5, 106403. https://doi.org/10.1088/2053-1591/aadac0 (2018).

-

Kite, S., Sathe, D., Patil, S., Bhosale, P. & Garadkar, K. Mater. Res. Express 6, 026411 ; https://doi.org/10.1088/2053-1591/aaed81. (2018).

-

Guo, D. et al. Self-Powered ultraviolet photodetector with superhigh photoresponsivity (3.05 A/W) based on the GaN/Sn:Ga2O3 Pn junction. ACS Nano. 12, 12827–12835. https://doi.org/10.1021/acsnano.8b07997 (2018).

-

Lin, S., Lu, Y., Xu, J., Feng, S. & Li, J. High performance graphene/semiconductor Van der Waals heterostructure optoelectronic devices. Nano Energy. 40, 122–148. https://doi.org/10.1016/j.nanoen.2017.07.036 (2017).

-

Mottram, D. Quasi two-dimensional dye-sensitized In2O3 phototransistors for ultrahigh responsivity and photosensitivity photodetector applications. ACS Appl. Mater. Interfaces. 8, 4894–4902. https://doi.org/10.1021/acsami.5b11210 (2016).

-

Chang, P. H. Ultrasensitive photoresponsive devices based on Graphene/BiI3 Van der Waals epitaxial heterostructures. Adv. Funct. Mater. 28, 1800179. https://doi.org/10.1002/adfm.201800179 (2018).

-

Wang, Y. et al. Solution-processed MoS2/Organolead trihalide perovskite photodetectors. Adv. Mater. 29, 1603995. https://doi.org/10.1002/adma.201603995 (2017).

-

Wang, S., Wen, J., Feng, L. & Yang, X. High temperature resistance and wide-spectrum detection flexible photodetectors based on PbS quantum dots/Bi2S3 nanorods. Mater. Sci. Semiconduct. Process. 198, 109738. https://doi.org/10.1016/j.mssp.2025.109738 (2025).

-

Zhang, X. et al. Growth of si/pbs heterostructure infrared photodetectors for NIR detection. ACS Photonics. 11, 1197–1204. https://doi.org/10.1021/acsphotonics.3c01720 (2024).

-

Schwanninger, R. et al. Highly responsive mid-infrared metamaterial enhanced heterostructure photodetector formed out of sintered pbse/pbs colloidal quantum Dots. ACS Appl. Mater. Interfaces. 15, 10847–10857. https://doi.org/10.1021/acsami.2c23050 (2023).

-

Luo, M. et al. A broadband photodetector based on PbS quantum dots and graphene with high responsivity and detectivity. Nanomaterials 13 (1996). https://doi.org/10.3390/nano13131996. (2023).

-

Yu, L. et al. Fast-response photodetector based on hybrid Bi2Te3/PbS colloidal quantum dots. Nanomaterials 12, 3212. https://doi.org/10.3390/nano12183212 (2022).

-

Wang, X. et al. Amorphous zno/pbs quantum dots heterojunction for efficient responsivity broadband photodetectors. ACS Appl. Mater. Interfaces. 12, 8403–8410. https://doi.org/10.1021/acsami.9b19486 (2020).

-

Peng, M. High-performance flexible and broadband photodetectors based on PbS quantum dots/zno nanoparticles heterostructure. Sci. China Mater. 62, 225–235. https://doi.org/10.1007/s40843-018-9311-9 (2019).

-

Qiao, K. et al. Efficient interface and bulk passivation of PbS quantum Dot infrared photodetectors by PbI2 incorporation. RSC Adv. 7, 52947–52954. https://doi.org/10.1039/C7RA10422G (2017).

-

Zheng, Z., Gan, L., Zhang, J., Zhuge, F. & Zhai, T. An enhanced UV–Vis–NIR and flexible photodetector based on electrospun ZnO nanowire array/pbs quantum Dots film heterostructure. Adv. Sci. 4, 1600316. https://doi.org/10.1002/advs.201600316 (2017).

-

De Iacovo, A., Venettacci, C., Colace, L., Scopa, L. & Foglia, S. PbS colloidal quantum dot photodetectors operating in the near infrared. Sci. Rep. 6, 37913. https://doi.org/10.1038/srep37913 (2016).

Acknowledgements

Hemant Tarkas is grateful to Savitribai Phule Pune University (SPPU) for the financial support received under the postdoctoral fellowship (PDF) program. Sandesh R. Jadkar thanks the Indo-French Centre for the Promotion of Advanced Research (CEFIPRA), Department of Science and Technology, New Delhi, and the Ministry of New and Renewable Energy, Government of India, New Delhi, for their special financial support. Finally, Shashikant P. Patole would like to thank Khalifa University of Science and Technology, Abu Dhabi, UAE, for its financial support through the internal fund for high-quality publications.

Funding

Indo-French Centre for the Promotion of Advanced Research-CEFIPRA, Department of Science and Technology, New Delhi, the Ministry of New and Renewable Energy, Government of India, New Delhi, and Khalifa University of Science and Technology, Abu Dhabi, UAE.

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Tarkas, H., Kandivkar, D., Rokade, A. et al. Biogenic synthesis of PbS nanoparticles by Micrococcus luteus and their application in high-performance photodetectors. Sci Rep 15, 26993 (2025). https://doi.org/10.1038/s41598-025-12559-6

-

Received:

-

Accepted:

-

Published:

-

DOI: https://doi.org/10.1038/s41598-025-12559-6