Chief Technology Officer

Cytiva

2026 will be a pivotal year for biopharma. From digital transformation to an AI revolution to more sustainable technologies, the forces driving change are redefining how therapies are discovered, developed, and delivered. At Cytiva, we’re seeing six key trends shaping the industry’s future into a more agile, intelligent, and patient-centric industry.

Digitalization unlocks control

Digitalization is no longer a future ambition; it’s a present necessity. In 2026, we’ll see digital technologies becoming deeply embedded across the biomanufacturing life cycle, enabling faster, more reliable, and more flexible operations.

Prescriptive batches, powered by machine learning and digital twins, are transforming how manufacturers detect and prevent failures. The predictive insights gained from digital twins will help reduce batch loss and bring us closer to the industry’s vision of “real-time-release,” resulting in faster delivery of therapies and fewer disruptions to supply chains.

Digitally enabled plants are also becoming the norm. Automation, robotics, and mixed reality (MR) training are streamlining operations, accelerating technology transfers, and boosting retention rates. These tools are not just improving efficiency by reducing downtime; they’re empowering operators and securing supply.

Flexible intensified manufacturing

As therapeutic modalities trend towards more personalized treatments, batch sizes are becoming even more varied, as smaller batches become more prevalent. Modular and single-use systems make it possible to quickly scale production out or down, supporting everything from large-scale vaccine rollouts to small-batch, personalized therapies. These systems reduce changeover time and cost while minimizing cross-contamination risks and improving facility utilization.

Alongside single-use systems, process intensification becomes another hallmark of flexible manufacturing, increasing facility output and process yields. This pertains to upstream unit operations like perfusion technology, but also to downstream purification technologies.

Flexible automation, digitalization, and standardization are also streamlining tech transfer and enabling faster adaptation to shifting demand. Whether in clinical phase production or commercial scale, the ability to reconfigure processes quickly is essential for staying competitive.

AI-powered bioprocessing

Artificial intelligence (AI) is on everyone’s mind, and for good reason. AI is revolutionizing biopharma from molecule design to manufacturing scale-up. In 2026, AI will become the connective tissue across the value chain, enabling smarter decisions and faster innovation. In the latest Biopharma Index, we found that high-growth firms are significantly more likely to use technologies such as AI, automation, and data analytics across drug development, clinical trials, and supply chains, suggesting that digital maturity underpins resilience, speed, and competitiveness.

In pharma, drug discovery AI is now integral to workflows, like CRISPR technology optimizing guide RNA design. These tools accelerate target and drug discovery, predicting off-target effects, and accelerating human-relevant models. Hence, AI is helping to reduce development timelines and improve safety profiles.

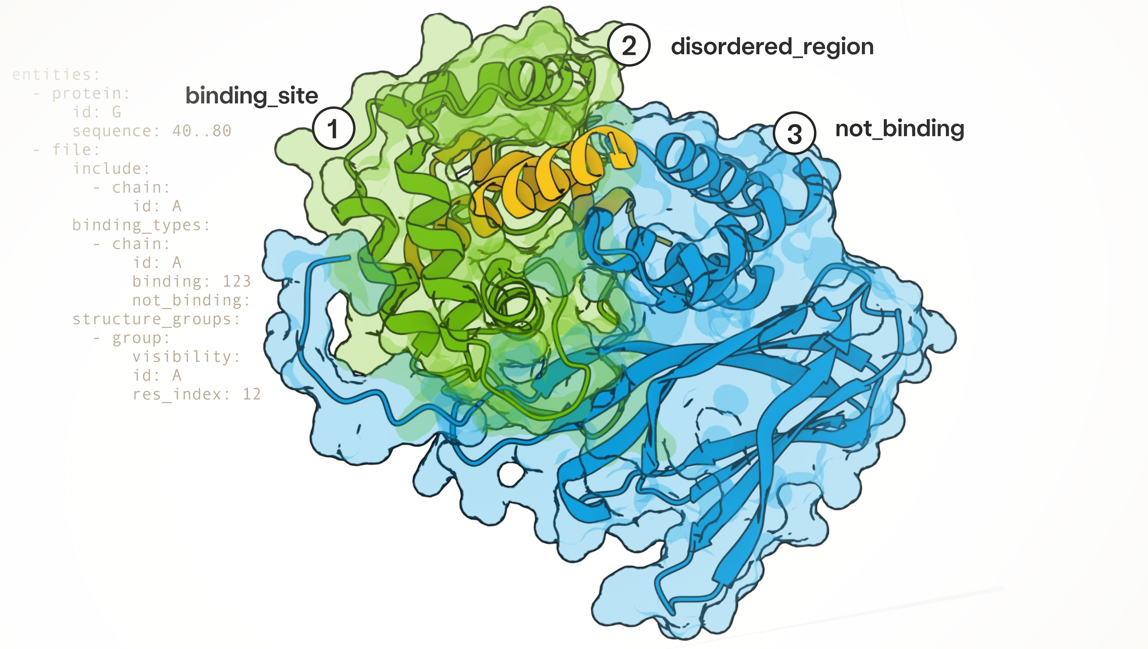

In protein drug discovery, disruptive molecular design tools like Bindcraft, RFAntibody, and BoltzGen (to name only a few) are unlocking new protein structures1, massively reducing the requirements for wet lab experimentation. These new tools can enable therapeutic candidates that were previously inaccessible since they allow researchers to explore vast molecular design spaces2 in silico, dramatically accelerating timelines and expanding the possibilities for novel biologics.

In manufacturing, AI is tackling the unpredictability of biological systems. Traditional statistical models, and even Large Language Models (LLMs), often oversimplify complex interactions, but systems such as Graph Neural Networks (GNNs) can address biological complexity. Instead of treating data points as isolated, GNNs understand the web of relationships and use that understanding to make smarter predictions. The ultimate realization of it is that a process runs optimally and consistently.

Data-driven collaboration

Data is the currency of collaboration. As biopharma companies seek to accelerate development and improve scalability, shared intelligence will become a strategic asset.

Foundation models—large-scale AI models trained on aggregated data—are enabling companies to build predictive tools that can be fine-tuned for specific products and facilities. Federated learning allows these models to be trained across multiple organizations without compromising proprietary data, fostering industry-wide innovation.

This approach mirrors the success of LLMs in other industries and offers a blueprint for bioprocessing. By integrating data across development, manufacturing, and quality control, companies can break down silos and make faster, more informed decisions.

Federated learning is also emerging as a solution to the “low n” problem in bioprocessing, where limited data from early-stage runs hampers model development. By training models across distributed datasets without compromising privacy, companies can build robust, scalable solutions tailored to their unique processes.

CRISPR’s shift to real-world impact

CRISPR technology is entering a transformative phase, moving from a drug discovery tool toward an actual treatment paradigm. This is exemplified by the recent medical success of a personal gene-editing therapy using CRISPR to treat Baby KJ. This major milestone demonstrates technology’s potential for treating rare and life-threatening diseases.3

Expanding CRISPR’s therapeutic capabilities requires precision editing tools. The two gaining traction for their precision and reduced off-target effects are prime editing and base editing. Base editing is a technique that allows scientists to directly convert one DNA base into another without cutting the DNA double helix. Prime editing is a newer and more versatile technique that can insert, delete, or replace DNA sequences with high precision. These tools allow single-nucleotide changes without double-stranded breaks. This gives CRISPR’s therapeutic scope the potential to expand beyond treating monogenic diseases like Tay-Sachs to certain forms of cystic fibrosis and other non-monogenic disorders like acute lymphoblastic leukemia, or autoimmune disorders like lupus erythematosus. By engineering a patient’s T cells to express a recombinant chimeric antigen receptor (CAR), the patient’s immune response is activated to deplete the respective tumor cells4 or, in the case of autoimmune diseases, B cells producing autoantibodies. If successful in clinical development, such treatments will democratize access to genomic medicines, which today are very costly because of their complex manufacturing technologies or lack of availability for many ultra-rare and rare diseases.

The societal need for these democratized in vivo cell therapies is exemplified by the mobilization of governmental funding, such as in the U.S. There, the Advanced Research Projects Agency for Health (ARPA-H) provides research funding to build high-payoff capabilities or platforms to drive biomedical breakthroughs and accelerate better health outcomes for everyone. Programs falling in this category under ARPA-H are EMBODY, GIVE, and THRIVE. Horizon Europe Health Cluster Calls and Eurostars Programs are analogous funding mechanisms in Europe.

Sustainability drives innovation

In 2026 and beyond, sustainability will be a strategic imperative for the biopharma industry. Our Global Biopharma Index found that 62% of executives rank sustainability as their top priority for the next five years, despite the cost and geopolitical pressures they are currently facing. Sustainability is, and will continue to be, a key driver of operational efficiency, innovation, and resilience.

Single-use technologies are on the rise since they enable rapid changeovers and reduce resource-intensive cleaning processes. In multi-product facilities, closed single-use systems allow for lower safety classifications, such as class D cleanrooms, which significantly reduce energy consumption and waste.5 The next frontier of single-use sustainability is addressing the plastic waste opportunity––innovation is poised to play a key role here.

Development and application of new technologies, including sustainable raw materials for single-use consumables, as well as innovative end-of-life technologies, are vital to enabling the sustainable transformation of single-use bioprocessing.6 Manufacturers of single-use consumables will increasingly differentiate themselves through the International Sustainability and Carbon Certification (ISCC Plus), as recently exemplified by the use of biobased resins for Cytiva’s sustainable lab filtration products. Fundamentally new materials, bioderived and biodegradable, are on the horizon for pharma applications, with promise to bring carbon neutrality and circularity to single-use products.

Life cycle assessments (LCAs) will remain a key tool to guide smarter decisions across product development. For example, MabSelect PrismA was designed to offer higher purification efficiency than its predecessor, while also providing a reduced carbon footprint. Automation, such as inline buffer conditioning, is also minimizing raw material consumption and cleanroom space requirements.

PrismA was designed to offer higher purification efficiency than its predecessor, while also providing a reduced carbon footprint. Automation, such as inline buffer conditioning, is also minimizing raw material consumption and cleanroom space requirements.

The result? A future where therapies are developed with unprecedented speed and precision, tailored to each patient’s unique needs and to industry’s big geopolitical and environmental challenges.

As we enter 2026, we will witness (and contribute to) biopharma’s profound transformation. Digitalization, AI, data-driven collaboration, flexibility, and sustainability are not just trends; they’re the building blocks of a smarter, more resilient future in the biopharmaceutical industry.

References

1. Ghafarollahi A, Buehler MJ. Sparks: Multi-Agent Artificial Intelligence Model Discovers.

2. Koh, HY; Zheng, Y; Yang, M; Arora, R; Webb, GI; Pan, S; Li, L; Church, GM, AI-driven protein design, Nature Reviews Bioengineering, 2025.

3. Kassim SH PhD, Indurthi V PhD, Musunuru K MD PhD, et al. Patient-Specific In Vivo Gene Editing to Treat a Rare Genetic Disease. N Engl J Med 2025 VOL. 392 NO. 22.

4. Xu, J; Lin, L; Xie, V; et al. In-vivo B-cell maturation antigen CAR T-cell therapy for relapsed or refractory multiple myeloma. The Lancet, Volume 406, Issue 10500.

5. Scheuermann, A. Closed systems and single-use technology. Powtech Technopharm. October 2024:

6. Charles Granger, Ali Altamimi, Yoel Cortes-Pena, et at. Recycling of Single-Use Multilayer Plastics for Biomanufacturing with Solvent-Targeted Recovery and Precipitation. ACS Sustainable Chemistry & Engineering 2025 13 (40), 16930-16945.

Beate Mueller-Tiemann, PhD, is Chief Technology Officer at Cytiva.

The post An Agile, Intelligent and Sustainable Future: Biopharma Trends to Watch appeared first on GEN – Genetic Engineering and Biotechnology News.