At a conference early next year, biologics manufacturers will be encouraged to develop a chemistry, manufacturing, and controls (CMC) management strategy for their reference material early in development to avoid later potential risks.

The talk, by French biotech consultancy INITS, aims to help companies avoid a chaotic rush during late-stage development. According to CMC expert Yann Gallais, PhD, regulators often expect more details about both products and the control of processes at this stage, and this can catch companies out if they haven’t made a clear plan.

“Agencies want you to have a deep characterization of your reference material,” Gallais says. “That means you have to know [a lot] about it [and, to achieve that], you likely need to think about performing assays only used once or twice in the whole life of your product,” he says.

According to Gallais, companies often don’t focus on creating a detailed plan for CMC and reference materials upfront because of a lack of staff, and that, although critical, at early stages can feel like a low priority.

“Everything needs to be done by yesterday. The focus is on bringing the drug to the patient, and people focus on more urgent things, such as process development,” he says.

However, although agencies will be happy to accept data on the strength of a reference material in a Phase I trial, and strength and potency in Phase II, by Phase III, says Gallais, they require a list of assays for deep characterization of the product.

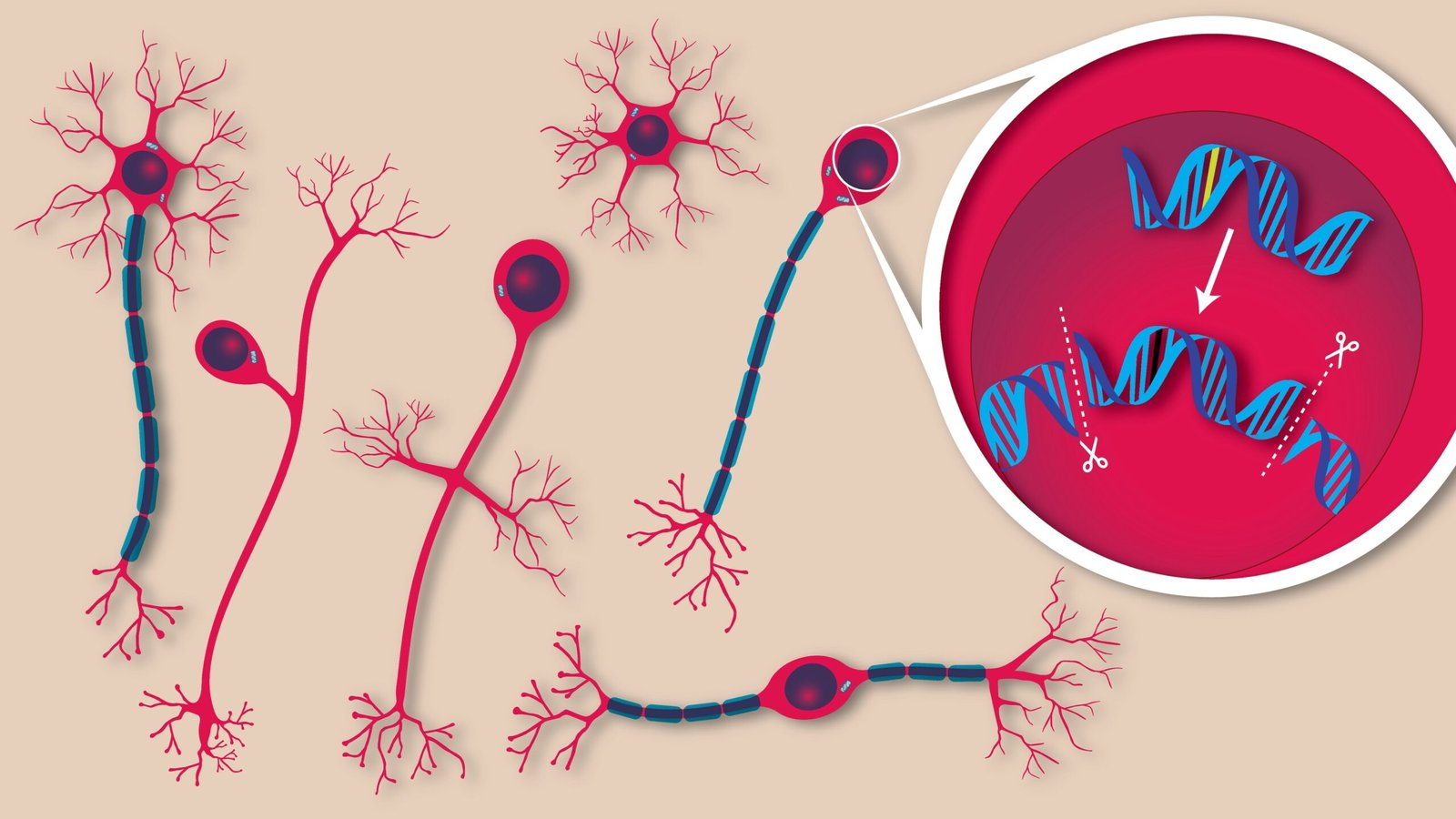

For emerging therapies, such as gene therapies, for example, they might want detailed information about DNA contamination of the product, he says.

If companies have left forming their CMC plan too late, they may end up being forced to perform a huge number of assays in a massive rush, which in turn risks revealing problems with the product that will cost delays and money to solve.

“From a biotech perspective, the less you know, the fewer problems you have. If you only focus on a small number of things, it feels easier to manage, but once you start discussing with agencies, this begins to be a big problem,” Gallais says.

In addition, companies need to plan for keeping back a sample for testing and, with new advanced therapies, this can be expensive if it’s not a tiny sample manufactured as part of a plan, he says.

The post Biologics Manufacturers Urged to Develop QC Plans Early appeared first on GEN – Genetic Engineering and Biotechnology News.