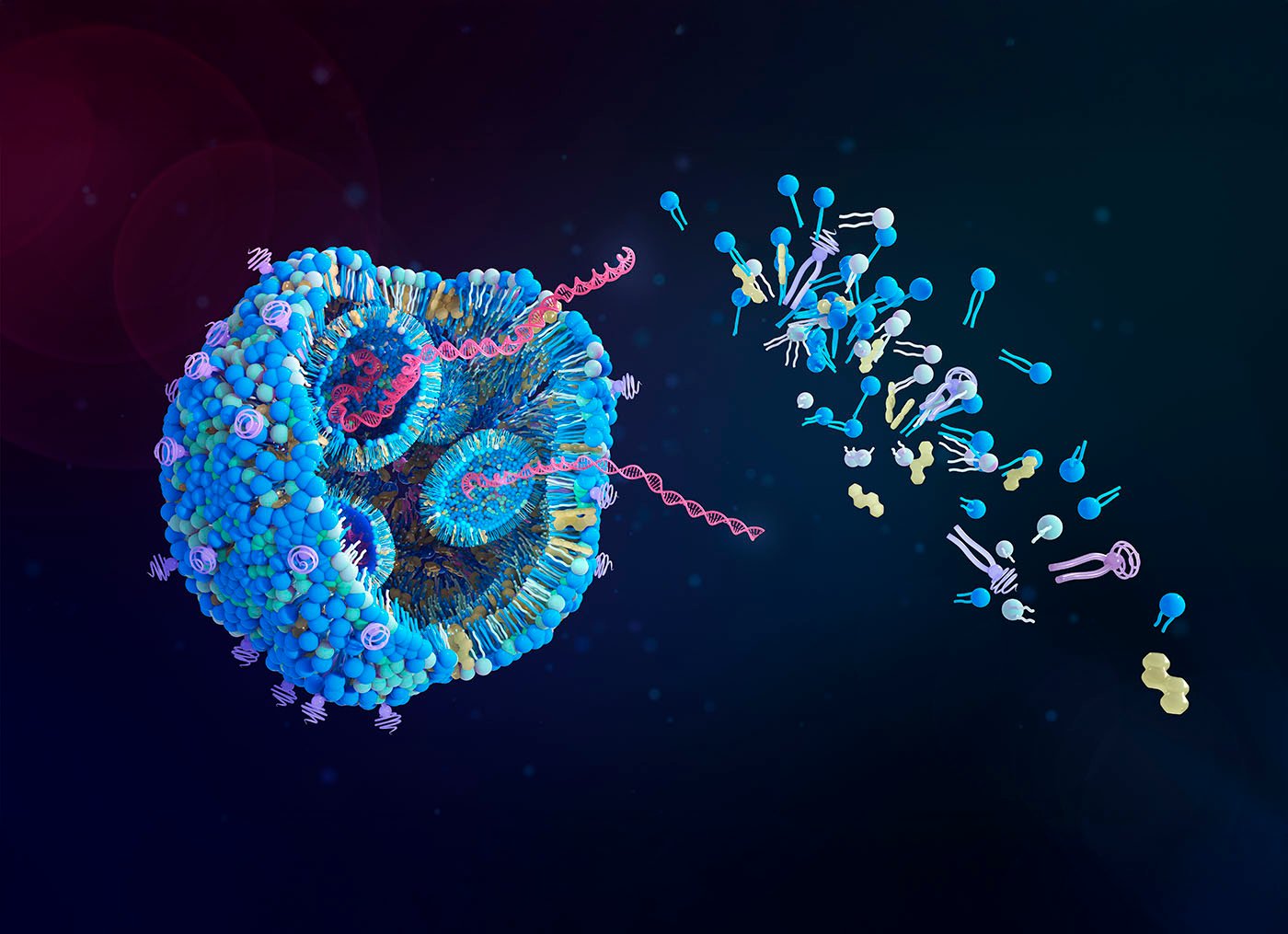

Continuous manufacturing makes monoclonal antibody production faster, cheaper, and greener, say researchers, who predict that industry adoption of the approach will accelerate in response to competitive pressure.

Most therapeutic antibodies are made as batches, using discrete processes that run for a defined period. This, in large part, reflects the success of early drugs like Enbrel, Humira, and Avastin, which established fed-batch processes as the standard approach.

However, as the mAb manufacturing sector matures, the inefficiencies and inconsistencies associated with batch production are becoming an issue, say the researchers behind a new study.

“Currently, the industry is confronting new challenges, such as increased competition post-patent expiration, managing diverse and changing biologic portfolios, and expanding patient access globally.

“These pressures have highlighted the need for greater manufacturing flexibility, sustainability, and cost reductions,” they write.

Continuous improvements

And, in terms of flexibility, sustainability, and cost, continuous-mode manufacturing has advantages over both standard fed-batch and intensified and optimized fed-batch (IO-FB) approaches.

“In continuous bioprocessing, the reactor operates continuously, leading to a more homogeneous output. This consistency minimizes variations in product quality and reduces the probability of out-of-specification drug substances,” the authors write.

There are also benefits from an operational standpoint, according to the authors, who cite the early identification of faults as an example.

“Within a continuous manufacturing platform, real-time monitoring allows for early defect detection, whereas, in batch processing, defects may not be identified until the entire batch is completed, making it harder to maintain consistent quality.”

The team looked at other metrics and found similar benefits. For example, compared with an optimized fed-batch process, continuous manufacturing reduced costs by an average of 23% and CO2 emissions by up to 54%.

In addition, because continuous bioprocessing technologies are more compact than those used for batch-mode production, the manufacturing facilities required can be up to 51% smaller than traditional plants.

Environmental impact

Continuous mAb manufacturing processes are also more environmentally friendly than traditional methods, according to the authors, who cite a reduction in plastic waste and lower carbon emissions as examples.

“The continuous process, on average, produces 57% less plastic waste compared with IO-FB,” they write, adding that “the size and number of plastic bags used for IO-FB are major contributors to this difference. The higher number of batches required for IO-FB processes and the larger size of equipment both impact the size and number of plastic bag assemblies.”

Also, according to the authors, continuous processes produce, on average, 54% less CO2 than IO-FB processes. Again, they cite the reduced facility footprint as key.

“For continuous processes, smaller equipment size and a smaller facility footprint mean lower energy requirements for the process and building, and, therefore, a significant reduction in CO2 emissions.”

The post Continuous Manufacturing Helps mAb Firms Innovate and Cut Costs appeared first on GEN – Genetic Engineering and Biotechnology News.