When most people think of bioprocessing, they think of the production of a biologically based drug. Ask an AI-based assistant to define bioprocessing, and it returns something like this: “Bioprocessing is a method that utilizes living cells or their components, like enzymes, to create desired products.” Even in healthcare, that’s a pretty broad definition, one that goes far beyond drugs. Consequently, many more methods of bioprocessing might lie ahead. One of them could be the use of bioprinting, which many consider a subset of biomanufacturing, and can be part of bioprocessing, depending on the context.

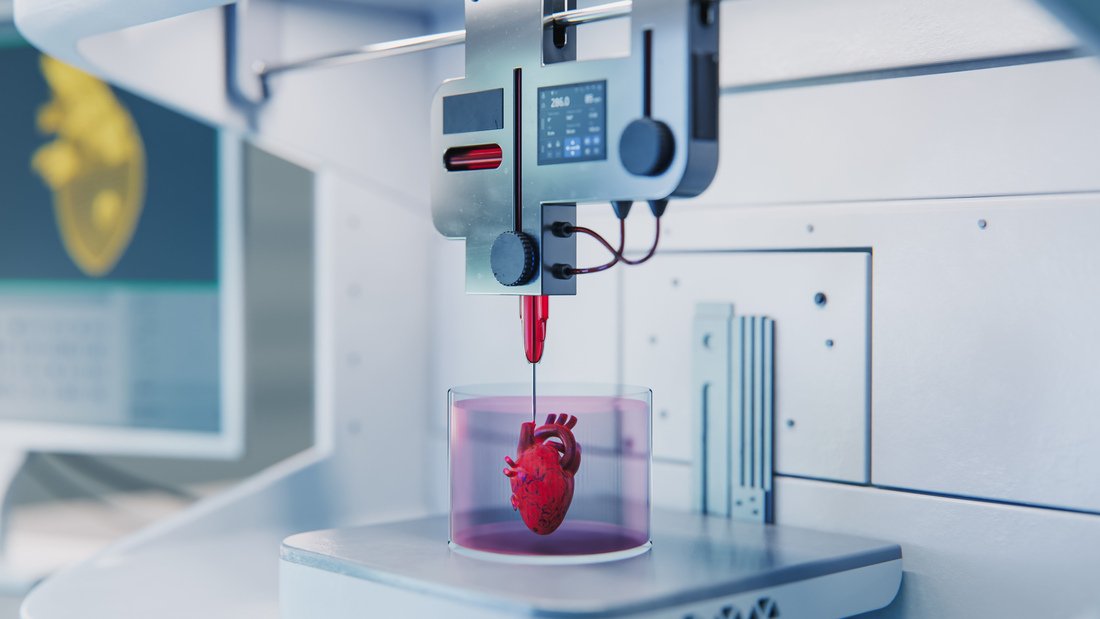

Instead of treating tomorrow’s severe heart diseases with a drug, for example, bioprinting might just make a new heart for a patient. As a start for that sort of future for bioprocessing, Yong He, PhD, professor of mechanical engineering at Zhejiang University in Hangzhou, China, and his colleagues recently described protocols that create organ-like tissues with bioprinting.

As these scientists noted: “Projection-based three-dimensional bioprinting offers an approach for manufacturing biomimetic tissues with complex spatial structures and bioactivity, presenting potential for creating implantable organs or organoids to test drug response.”

The key challenge that this approach addressed is the long printing time required for organ-sized structures without damaging the health of cells. Plus, existing bioinks often fail to provide the fine detail required for organ-scale printing.

Yong and his colleagues developed a process that uses special additives, including the Ficoll 400 density gradient to make the bioink more uniform and pH calibration to keep cells alive during printing. With only basic lab and biotech knowledge, users can produce complex, highly detailed tissues that remain viable for at least a week.

In tests, the method successfully printed a dense, cube-shaped tissue—10 mm per side, 10 million cells per µL—with over 82% cell survival after seven days. Preparing the bioink and printing took about five hours, followed by a week of culture for the tissue to develop.

Moreover, the method can be adapted for custom 3D models, different cell combinations, and various applications such as disease modeling, regenerative medicine, and drug testing. For example, Yong’s team reported: “Based on the biocompatibility of [this] bioink system and its role in tissue regeneration, we anticipate that our methodology can be applied to various targets, such as bone, cartilage, nerve, liver, skin, trachea, blood vessels, and muscle.”

Bioprinting is unlikely to replace biopharmaceutical manufacture anytime soon. In the future, though, treating a failing organ through biopharmaceuticals might give way to a transplant with a bioprinted substitute.

The post Is Bioprinting in Bioprocessing’s Future? appeared first on GEN – Genetic Engineering and Biotechnology News.