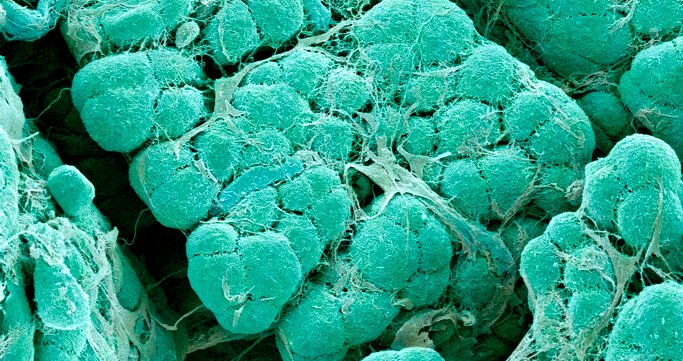

The yeast Kluyveromyces lactis (K. lactis) could become a highly productive, sustainable, cost-effective energy source for cell-free protein synthesis (CFPS) as biopharmaceutical manufacturers strive to reach a circular economy.

Key points in its favor include a three-to-fourfold increase in protein yields compared to Pichia pastoris (P. pastoris) CFPS systems, and the low cost of lactose, which K. lactis not only can use as its only food source, but can also metabolize under aerobic conditions.

A team led by Karen M. Polizzi, PhD, professor, Imperial College London, developed a CFPS system using K. lactis to synthesize both erythropoietin (EPO) and green fluorescent protein (deGFP). Notably, the ability to metabolize lactose is only present in the domestic variant, K. lactis var. lactis. The wild variant, K. lactis var. drosophilarum, cannot metabolize lactose.

After evaluating 128 CFPS mixes to synthesize EPO and deFGFP, the team reported that optimal synthesis for both proteins occurred at 30° C, “with significantly reduced activity at 24° C and 37° C for EPO.” The optimum resuspension-to-pellet ratios with which to achieve the highest protein concentrations were 2.5:1 and 1:1. The scientists studied a range between 0.5:1 and 2.5:1 with a 2.5-minute homogenization time. “Insights thus far suggest that protein concentration is a useful indicator of extract quality,” they noted.

“Homogenization time significantly influenced CFPS yields and extract protein concentrations,” Polizzi and colleagues noted. When the homogenization time was extended beyond 2.5 minutes, endpoint signal strength for EPO synthesis peaked at six minutes for the 1:1 resuspension, and at four minutes for the 2.5:1 resuspension. For deGPF production, endpoint signal strength peaked at three minutes for the 1:1 resuspension, and at six minutes for the 1.5:1 resuspension.

Admittedly, K. lactis grows more slowly in lactose-based media than in glucose-based media, the researchers pointed out. That delay may be offset by robust extracts that maintained high levels of protein synthesis in CFPS and “signals that were at least doubled…suggesting higher yields,” they said, as well as by the significant benefit of inexpensive feedstocks, such as whey.

The reaction conditions this team identified “consistently outperformed the initial P. pastoris-optimized reaction mix in terms of deGFP and EPO production,” Polizzi and her team determined. They hypothesize a further benefit during storage, as “lactose can function as a cryoprotectant.”

“We found the use of lactose to substantially enhance CFPS productivity when used not only as a carbon source for cell growth for extract preparation but also as an energy source when supplemented in the reaction mix,” they concluded. Consequently, this generally-regarded-as-safe (GRAS) yeast can be a cost-effective production vehicle for enzymes and antibodies, as well as heterologous proteins.

The post Lactose-Eating Yeast Boosts Yields and Cuts Costs for Cell-Free Protein Synthesis appeared first on GEN – Genetic Engineering and Biotechnology News.