- Review

- Open access

- Published:

- Tikam Chand Dakal1,

- Nitesh Singh2,

- Amandeep Kaur3,

- Prabhsangam Kaur Dhillon3,

- Janvi Bhatankar4,

- Ramovatar Meena5,

- Rakesh Kumar Sharma6,

- B. R. Gadi7,

- Bikram Sen Sahu5,

- Asmita Patel8,

- Buddha Singh8 &

- …

- Kajal Kumari5

Biotechnology for Biofuels and Bioproducts volume 18, Article number: 79 (2025) Cite this article

Abstract

Microbial fuel cells (MFCs) have emerged as a promising technology to convert biomass and organic waste into electricity, offering an eco-friendly and sustainable alternative to fossil fuels. Recent innovations in nanotechnology have significantly enhanced the performance and efficiency of MFCs by improving electron transfer rates, expanding surface areas, and optimizing the properties of anode and cathode materials. This review provides a detailed assessment of the fundamental and functional components of MFCs. These components include the anode, which facilitates the oxidation of organic matter, and the cathode, where the reduction of oxygen or other electron acceptors occurs. Another critical component is the proton exchange membrane (PEM), which allows the transfer of protons from the anode to the cathode while preventing oxygen from diffusing into the anode chamber. In addition to discussing these key elements, the article explores the role of various microorganisms involved in MFCs. These microorganisms, which include both naturally occurring species and genetically engineered strains, play a vital role in facilitating extracellular electron transfer (EET), a process that enables the conversion of chemical energy stored in organic compounds into electrical energy. We analyze different biomass pretreatment strategies, such as physical, chemical, and biological approaches, that enhance the breakdown of lignocellulosic biomass to improve energy output. Furthermore, the review highlights optimization techniques for improving biomass-powered MFC performance, such as electrode modification, pH control, and organic loading rate management. The application potential of MFCs is extensively discussed, covering bioremediation, wastewater treatment, biosensors, and power generation, with a particular focus on MFC-based biosensors for environmental monitoring and medical diagnostics. Despite their immense potential, challenges such as low power output, biofouling, and high operational costs hinder large-scale commercialization. To address these issues, we propose innovative strategies, including the integration of nanomaterials, electroactive microorganisms, and advanced membrane designs, to enhance the efficiency and reliability of MFCs. We conclude that nanotechnology-enabled MFCs, combined with engineered microbes and optimized system designs, hold immense potential for revolutionizing sustainable energy generation and biosensing applications, paving the way for a cleaner and more efficient future.

Introduction

Nanotechnology, the manipulation of matter on a molecular and atomic scale, has opened up new possibilities in various fields, including energy production [1] The increasing need for energy, particularly from fossil fuels based on hydrocarbons, and the growing awareness of environmental problems like climate change has encouraged researchers to discover new technological procedures that will primarily use renewable energy sources to generate clean, sustainable energy [2]. The generation of electricity through the irreversible use of fossil fuels has prompted scientific interest in the use of biotechnology for the energy extraction of diverse organic waste sources [3]. MFCs have significant promise to enable a smooth shift from fossil fuel-dependent energy to clean and sustainable energy sources [4]. It is generally agreed upon that the most promising source of renewable energy is the conversion of renewable organic matter utilizing MFCs [5].

Two cutting-edge technologies that have the potential to change how we produce and use energy completely are nanotechnology and microbial fuel cells [6]. Nanotechnology has revolutionized the field of energy generation and storage with MFCs, where bacteria generate electrical energy by oxidizing organic matter in wastewater [7]. By combining the power of nanotechnology with microbial fuel cells, researchers are exploring new ways to produce clean and sustainable energy sources [8]. This technology produces bioenergy from multiple substrates, including complex sources such as urban and industrial wastewater and biomass wastes [9]. Additionally, they can help minimize the negative environmental effects associated with particular alternative energy systems [10].

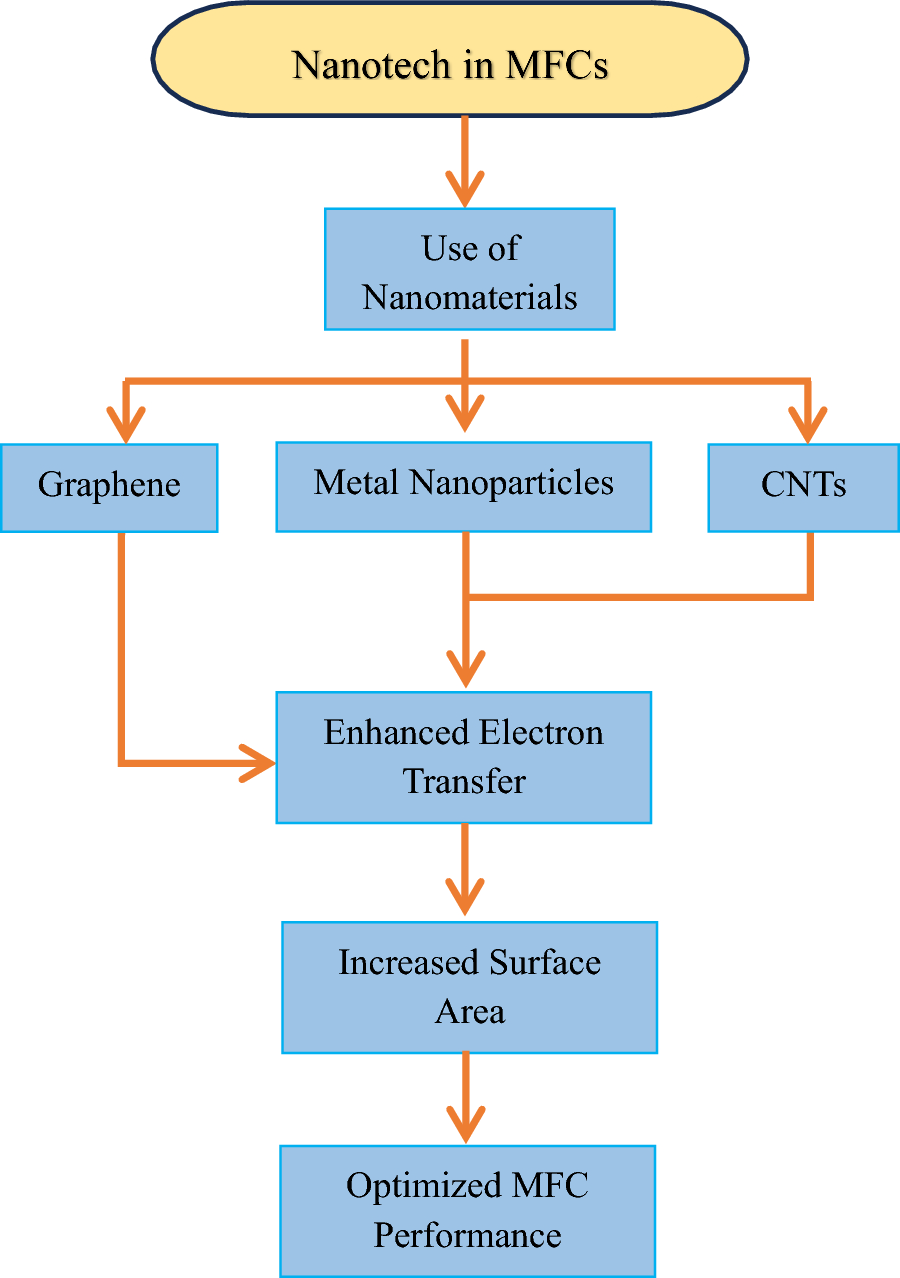

MFC is a promising technology that can enable the production of power from renewable biomass and complex organic wastes. A variety of biodegradable organic substances, including proteins, carbohydrates, agricultural waste, and industrial effluents, can be used as feedstock in MFCs to generate energy [11]. The availability and abundance of low-cost waste materials and living entities like bacteria and plants are the key reasons MFCs are used to upcycle or downcycle waste into valuable products [12]. Furthermore, microbial fuel cells could be used in isolated or off-grid areas, offering a dependable power supply in places where conventional energy sources might be few or absent [13]. This makes microbial fuel cells an attractive option for sustainable energy production, as they offer a renewable and environmentally friendly alternative to traditional fossil fuels [14]. Additionally, the materials utilized for the anode and cathode, the catalyst substrate, and the polymer electrolyte membrane (PEM) all have a major impact on the performance of MFCs [15]. Carbon nanotubes, metallic nanomaterials, and graphene have been widely used in nanotechnology-based energy generation using MFCs (Fig. 1). Additionally, a variety of metallic elements have been employed to improve the mechanical strength, corrosion resistance, and electrical conductivity of MFCs. These elements include carbon paper, graphite, reticulated vitreous carbon, nickel sheets, copper sheets, and stainless-steel mesh [16]. Nanotechnology has the potential to improve the performance and efficiency of microbial fuel cells through the enhancement of electron transfer rates, the expansion of surface area for microbial adhesion, and the creation of novel materials with improved conductivity qualities [17]. In addition to that the special qualities of nanomaterials, like their high potential for recovery, stability, durability, reusability, and recycling, as well as their high enzyme loading, high adsorption capacity, high crystallinity, efficient storage, and catalytic activity, all contribute to the overall fuel system’s optimization.

The optimization and performance analysis of MFCs require expertise across multiple scientific and engineering disciplines, including electrochemistry, microbiology, materials science, environmental science, and chemical engineering [18]. While MFCs offer numerous benefits, several critical challenges must be addressed before they can be widely adopted. One of the primary limitations is the low power output of MFCs compared to conventional energy sources. Other significant obstacles include the high cost of anode materials for large-scale applications, inefficiencies arising from electrode material properties—such as surface area, charge transport, and catalytic behavior—and the complexity of system development and energy recovery processes. Additionally, the low efficiency of extracellular electron transfer (EET) between microbes and electrodes remains a major barrier, reducing the competitiveness of MFCs in the energy market. Optimizing electrode surface treatments has been shown to improve EET efficiency, but further advancements are needed to overcome this limitation [19].

Despite these advancements, the large-scale application of MFCs remains hindered by several challenges, including low power output, high operational costs, and limited extracellular electron transfer (EET) efficiency. Previous studies have primarily focused on improving individual components or microbial activity, but a comprehensive approach that integrates nanotechnology and microbial engineering to enhance overall MFC performance is lacking. In addition to that the potential of genetically modified electroactive microorganisms to boost EET and energy conversion efficiency has not been fully explored.

This review addresses these gaps by providing a systematic and holistic assessment of MFCs, emphasizing the synergistic role of nanotechnology and microbial engineering in optimizing performance. It explores strategies for enhancing electrode efficiency, improving microbial electron transfer, and utilizing genetically modified microorganisms to boost power output. By proposing innovative approaches, this review highlights future directions for the development of high-performance, cost-effective, and scalable MFC systems.

Problem statement

The increasing global demand for clean energy and the environmental drawbacks of fossil fuels highlights the need for sustainable alternatives. Microbial fuel cells (MFCs) offer a promising solution by converting organic waste into electricity, yet their large-scale application is hindered by low power output, high costs, and inefficient extracellular electron transfer (EET). Limitations in electrode materials, charge transport, and catalytic behavior further impact performance.

Nanotechnology has shown potential in enhancing MFC efficiency by improving electron transfer and optimizing electrode materials. However, research has largely focused on isolated improvements rather than an integrated approach combining nanotechnology and microbial engineering. In addition to that the potential of genetically modified electroactive microorganisms to enhance EET remains underexplored. This review addresses these gaps by evaluating the synergistic integration of nanotechnology and microbial engineering to improve MFC efficiency, optimize power output, and advance scalable, cost-effective bioenergy solutions.

To get over MFC bottlenecks, much work has been done to improve MFC efficiency by developing new materials and designs for the anodic/cathodic electrodes and separators, which are the major components of the systems. Various modified nanomaterials have also been employed for power enhancement in MFCs compared to traditional C-based materials [20]. It is feasible to optimize and enhance the performance and efficiency of microbial fuel cells using various nanostructured materials. These materials have high specific surfaces, improved transfer rates, and lower production and operating costs [21]. An improvement in these crucial elements raises the MFC’s total performance, which suggests a higher power output. The table below shows the evolution and quantitative performance of the microbial fuel cell in terms of its design (Tables 1).

Fundamental and functional components of MFCs

MFCs are new biochemical devices that generate power through the utilization of microbes. The bacteria utilize the process of microbial electrogenesis to transform organic materials into energy. A traditional microbial fuel cell consists of four essential components: an anode, a cathode, an ion-permeable or proton exchange membrane (PEM), and an external circuit (Figs. 2 and 3, Table 2). Microorganisms play a fascinating role in bioenergy production and function as a biocatalyst, facilitating the movement of electrons from organic substrates to an electrode and generating energy in the process. For this, a variety of bacteria that are frequently found in soil, wastewater, activated sludge, and other areas can be used [29]. The contribution of these small power centers to sustainable energy is impressive and depends on many vital components.

A waste-to-wealth modal for biomass from household and agriculture waste for their use in bioelectricity production

Microbial fuel cells (MFCs)

Microorganisms function as active biocatalysts in MFCs, which are renewable energy devices that produce electricity. The original idea of microbial fuel cells was introduced by Potter in 1911 [30]. Anode and cathode, the two compartments of the MFC, are divided by a membrane. The positive electrode is found in the anode chamber, the negative electrode is found in the cathode chamber, and the two chambers are separated by the proton exchange membrane (PEM), which also permits the flow of protons from the anode to the cathode. Bacteria and chemical or organic waste can be found in the anode chamber. These bacteria break down organic or inorganic substances in the anode chamber 1 under anaerobic conditions at the site of the electron source processes. On the other hand, the cathode chamber’s air entry helps the cathode’s dissolved oxygen (O2) concentration drop. By promoting electron passage from the anode to the cathode via an external circuit, this method produces electrical energy [31]. The organic material utilized, the kind of bacteria (biocatalyst), internal resistance, the characteristics of the electrode material, the membrane, and the concentration of ions are some of the elements that affect the performance and efficiency of microbial fuel cells. The electrode materials are one of the most important factors in influencing the overall performance and efficiency of the MFC. Proton exchange membranes (PEMs) are also essential for the effective operation of MFCs. However, the microbial fuel cells can be separated into two categories based on how they are assembled. There are two types of microbial fuel cells: single chamber and double chamber.

Double chamber MFCs are structured similarly to traditional fuel cells, with distinct anodic and cathodic chambers separated by a permeable membrane known as a proton exchange membrane (PEM). This setup permits the maintenance of unique conditions in each chamber, facilitating more precise control over the electrochemical reactions. Dual-chambered MFCs can be designed in various geometries. The U-shape is a popular design in which the anode and cathode are placed on opposite arms, with the PEM at the base separating them. The H-shape is another well-liked design in which the PEM is positioned in the center and the anode and cathode are positioned on opposing sides. Sometimes, twin chamber MFCs are made up of two independent containers joined by a salt bridge. These arrangements put the electrodes farther apart since they are situated in distinct chambers. This greater separation may result in higher internal resistance, which could impair the MFC’s overall performance [32].

Single chamber MFCs have a porous air cathode on one side and an anode chamber on the other. Protons can go via the cathode, which absorbs oxygen from the surrounding air. Typically, the cathode is coated with platinum to enhance its functionality. Water is created when protons in the solution combine with oxygen from the air and electrons from the anode [33]. The efficiency of the MFC may be reduced if an excessive amount of oxygen enters the microorganisms at the anode through the air cathode. The cause-effect relationship arises because electrons tend to react directly with oxygen, bypassing the energy generation process. To address this problem, oxygen diffusion is limited by a cation exchange membrane (CEM) that is positioned between the anode solution and the air cathode. Many researchers have been drawn to single chamber MFCs because of their unique features and numerous advantages. Compared to double chamber MFCs, single chamber MFCs have a shorter distance between the anode and cathode, which reduces internal resistance and increases efficiency. Additionally, single chamber MFCs are simpler to operate and require less frequent changes of the oxidative media [34].

Biomass-fueled MFCs

Biomass, which includes organic materials like agricultural residues, wood, and algae, is an abundant renewable energy resource [35]. One of the most promising directions for the biomass energy sector is the direct conversion of biomass into the most common form of electric energy. Various biomass has been used as fuel sources to produce bioenergy in microbial fuel cells to date, including chitin, kitchen waste, orange peels, algal biomass, wheat straw hydrolysate, rice straw, corn stove, solid potato wastes, food waste, corn stalk biomass, lemon peel, and cow dung [36]. Therefore, a significant challenge is efficiently breaking down the complex structure of lignocellulosic biomass in the MFC’s anode chamber. If not properly degraded, this can reduce the power density of MFCs [37].

Nevertheless, many microorganisms struggle to effectively degrade the complex lignocellulosic structure, resulting in reduced MFC performance. To overcome this limitation, various pretreatment processes are essential to release reducing sugars from lignocellulose. These pretreatment methods include physical, acidic, alkali, and biological/enzymatic approaches. Physical pretreatment methods such as chipping, milling, and grinding enhance biodegradability of biomass in MFCs by reducing particle size and disrupting the crystalline structure of biomass. Studies indicate that reducing biomass particle size to below 0.4 mm significantly boost hydrolysis rates and yields making more material available for biodegradation in MFCs [38, 39]

Chemical pretreatment

In addition to that, pretreating biomass has been successfully accomplished by a variety of irradiation techniques, including ultrasonication, electron beams, X-rays, and gamma rays. For example, Pandit et al. found that, when dairy manure was pretreated with ultrasound, the maximum power density in MFCs was 241% higher than when the substrate was left untreated [40]. Acidic pretreatment is an effective chemical technique for increasing the efficiency of enzymatic hydrolysis and optimizing the energy conversion of lignocellulosic biomass in MFCs. This process causes the forces holding the components of biomass to break, which solubilizes the hemicellulose and reduces the cellulose. Fermentable sugars can be extracted from lignocellulosic biomass with especially high efficiency using concentrated mineral acids (CA) such as HCl and H2SO4. In the meantime, the pretreatment with diluted sulfuric acid shows a high reaction rate and greatly enhances the hydrolysis of lignocellulose [41] (Table 3).

Alkali pretreatment includes adding bases to biomass, which causes lignin to break down and increase its internal surface by swelling, a decrease in the degree of polymerization and crystallinity, and the breaking of connections between lignin and other polymers. The most often reported chemicals used in alkaline pretreatment are NaOH, KOH, and Ca (OH)2, and they usually require a longer reaction time, ranging from hours to days [42]. For biomass with low lignin concentration, like agricultural leftovers or grasses, alkali pretreatment is preferred; substrates with high lignin content, like woody biomass, are considered inappropriate for this technique. Research revealed that pretreating rice straw with sodium hydroxide (NaOH) for solid phase microbial fuel cells (SMFCs) produced a maximum power density of 140 mW/m2, which was 3.6 times more than that of SMFCs without treatment [43].

Biological/enzymatic pretreatment

Biological pretreatment, which usually happens in the first stage of hydrolysis along with other pretreatment procedures, involves employing microbial and enzymatic catalysts to break down the lignin structures in the cell wall. The crystalline structure of lignocellulosic biomass can be hydrolyzed and disrupted by certain bacteria and fungi, which increases sugar yields and improves MFC efficiency [44]. Unlike chemical methods that require strong acids, alkalis, or high temperatures and pressures, biological approaches generate fewer toxic by-products and have a lower environmental footprint [175]. Bacterial species belonging to, Ruminococcus, Cellulomonas, Clostridium, Erwinia, Bacteriodes, Bacillus and Streptomyces can produce cellulases. It has been discovered that lignocellulosic biomass is broken down by white-rot and soft-rot fungi by the production of several enzymes like laccases, polyphenol oxidases, lignin peroxidases, and manganese-dependent peroxidase. Despite this, the biological hydrolysis is too slow requiring 10 to 14 days, careful contamination control and a substantial space making it limited commercial use [45, 46].

Anode electrode

In MFCs, the anode material is a major factor in deciding the system’s power density. Its structure, morphology, and surface characteristics have a substantial impact on substrate oxidation, electron transfer, and bacterial adhesion, which in turn affects total MFC performance. It may be possible to modify conventional carbon- or metal-based anodes to reduce their inherent limits by utilizing different types of nanomaterials [78]. Specifically, nanomaterials provide significant increases to anode performance through surface area enhancement, improved electron transfer, biofilm growth, and improved bacterial oxidation reactions of organic waste [79]. The performance of MFCs can be directly impacted by these alterations, which can increase surface properties such as biocompatibility, bacterial adhesion, and electron transfer efficiency between the bacteria and the electrode surface. In single-chamber MFCs with brush anodes, anode biofilm maturation and the onset of stable cell performance typically occur within the first two weeks of operation, as evidenced by time-course electrochemical measurements indicating stabilized voltage output and internal resistance [178]. For instance, modifying anodes with carbon nanostructures like carbon nanotubes (CNT) and graphene has been shown to enhance power generation in MFCs [80]. Further research shows that a PANI-modified anode on a microbial fuel cell (MFC) might produce a maximum power density of 216 mW/m2 (20.52 W/m3) [81]. Additionally, the production of TiO2 nanosheets, or TiO2-NSs, has been studied. These nanosheets offer advantageous mass transport processes, wide surface areas for bacterial adhesion, good biocompatibility, and direct paths for electron transportation to the electrode [82, 176, 177]. Several limiting factors, including anode modification [115], pollutant characteristics [179], anode structure and materials [180, 181], and the nature of the organic substrate [182, 183], significantly influence the internal resistance and overall performance of MFCs.

Oxygen reduction reactions (ORR) and cathode electrodes

The performance of MFCs is significantly influenced by the cathode structure. A cathode with high porosity, electrical conductivity, surface area, and mechanical strength is ideal for MFC quality. Furthermore, High oxygen reduction rates (ORR) on cathodic surfaces are essential for improving the efficiency of microbial fuel cells (MFCs), and platinum–carbon (Pt–C)-based cathodes have been widely used to achieve this goal. Therefore, these cathodes have become a standard choice in MFCs. On the other hand, the high cost of Pt-based cathodes significantly limits their practical application, making large-scale deployment less feasible [84]. In addition to that, recent advances in nanotechnology have led to the development of shape-controlled Pt nanocatalysts with remarkably high ORR activities. These nanocatalysts enhance the performance of cathode electrodes by improving cell efficiencies, reducing Pt consumption, and boosting overall energy generation in MFCs [85].

The ORR activity for Pt3Ni (111) surfaces is similarly much higher than that for other aspects of Pt3Ni, according to theoretical and experimental investigations. Furthermore, because of the small surface curvatures, other shape-controlled nanocatalysts, like Pt-based nanoframes25, nanowires26, nanoplates27, and nanocages28, have been observed to display exceptionally high mass activities. It is also anticipated that these catalysts will consist of facets with large ratios and high specific surface areas [83].

Membranes or proton exchange membranes

Membranes are one of the key components influencing MFC performance. In MFCs, PEMs divide the anode and cathode chambers, permitting proton transfer but blocking oxygen transport. In MFCs, standard commercial membranes like Nafion and Ultrex are frequently used [86]. Nevertheless, these membranes have a few disadvantages, such as high prices, substrate, and oxygen cross-over, and biofouling [87]. By improving PEM characteristics, nanocomposite membranes speed up proton transfer and raise total MFC efficiency. TiO2 nanoparticles have also been used to alter a standard Nafion. Better ion conductivity than Nafion was achieved by the Ti–OH groups that formed in the TiO2-based nanocomposite membrane, increasing the number of exchange sites across the membrane. The nanocomposite, in contrast, may provide a higher water absorption. In comparison to commercial Nafion117, the nanocomposite membrane is superior in terms of proton conductivity, oxygen cross-over, and cost [88].

Another popular polymer used to create nano composite membranes in MFC building is SPEEK (sulfonated polyether ether ketone), which is less costly than nafion. Researchers have also created a nanocomposite made of SPEEK and sulfonated SiO2 that can serve as a proton exchange membrane for a single chambered MFC. [89] Moreover, there is reduced substrate leakage and a lower oxygen mass transfer coefficient in the nanocomposite membrane.

Optimization of biomass-fueled MFCs’ performance

Due to its high energy content and widespread availability, biomass is considered a promising fuel for MFCs. Additionally, MFCs are seen as a desirable technology for converting biomass into energy within the biomass business. Consequently, significant endeavors have been undertaken to enhance and refine biomass-powered microbial fuel cells (MFC) in recent years. Typically, as the majority of microorganisms are unable to directly break down biomass, pretreatment is necessary as a crucial step for biomass-powered microbial fuel cells (MFC). Several electroactive microorganisms (EAMs) were identified and studied for their ability to generate electricity in biomass-fueled MFCs. EAMs play a crucial role in the process of power generation. In addition to that there is significant interest in optimizing the process of MFC to enhance performance. This review provides a summary of several biomass substrates and electroactive microorganisms (EAMs) used in biomass-fueled MFCs. It also highlights current advancements in biomass pretreatment and performance optimization for biomass-fueled MFCs.

Optimization and operation conditions

One of the key elements of MFCs that influences both cathodic reactions and anodic microbial activity is pH, as it does in any biological system. Proton buildup in the cathode chamber would result in electrolyte alkalization and anolyte acidification. The ideal pH level is highly dependent on the kind of microbe. Research findings indicate that anodic biofilm fractured and cell count significantly dropped at pH < 5.0, and that MFC failure occurred at pH 4.0 as a result of alterations in the nature of the microbial community [47]. However, the MFCs could recover optimal electricity generation when pH was further readjusted to 7.0. In general, the operational pH range for most MFCs is reported to be between 6 and 9, with an optimum usually at neutral pH. The optimal pH range for achieving maximum power production in an acetate-fueled air–cathode MFC was found to be 8–10 [48, 49].

For optimal cell growth, the anodic microbiological reaction often required a neutral pH; in contrast, the cathodic reaction was better suited for a weakly alkaline pH. While it has been claimed that pH at the anolyte can be controlled using pH buffers such phosphate or bicarbonate (pH 7.0), this could lead to higher operating expenses, the need for effluent desalination, or an additional load of phosphorous removal [50].

Utilizing nearby carbon dioxide sources to generate a carbonate/bicarbonate buffer in situ by reacting with hydroxide ions in the MFC cathode is a step in the right direction and has been suggested as a viable, cost-effective solution to the MFC pH-buffering problem [51]. The properties of the biomass in MFCs and the type of anodic EAMs influence temperature. According to reports, microbial reactions slow down at very low temperatures, and eventually, MFCs cannot function in most situations [52]. According to certain studies, the starting temperature has a significant impact on how quickly an MFC’s biofilm forms and how long it takes to start up.

Consequently, higher temperatures result in faster MFC operation and stable biofilm formation, which boosts performance [53]. It has been investigated single-chambered and dual-chambered MFC operation at different temperatures ranging from 4 to 35 °C [54]. Tee et al. [55] determined that the optimal operating temperature for a microbial fuel cell with an adsorption system (MFC-AHS) using palm oil mill effluent as a substrate is 35 °C [56].

Effect of organic loading rat (OLR)

Biological oxygen demand (BOD) per volume unit of solution is the definition of organic loading rate (OLR), which is a measurement of the amount of oxygen needed by aerobic biological organisms to oxidize the organic matter in a solution at isothermal circumstances. For this reason, OLR is typically used to measure the mass rate of organic matter entering a reactor for the treatment of sludge or wastewater. OLR, also known as sludge loading rate (SLR), is essential to the efficient operation of MFCs since it directly affects the substrate conversion rate, which in turn determines the power density (PD) and current efficiency (CE) of MFCs. Variations in OLR can affect the electron transfer efficiency; as a result, energy generation in MFCs typically rises as OLR rises to an optimal point, after which additional OLR increases lead to a reduction in power output. A greater OLR increases the amount of feedstock that can be oxidized at the anode, which in turn increases power output and the electroactive biofilm’s metabolic activity. On the other hand, high OLR has been linked to decreased effectiveness in the processes that transfer electrons from the anode to the cathode, which lowers MFC performance overall [57].

Electrode modification

Materials for electrodes good electron conductivity, a sizable surface area, and biocompatibility for microbial adhesion are characteristics of microbial fuel cells. The characteristics of the electrode surface, such as porosity, hydrophilicity, and roughness, impact the production of biofilms and the subsequent generation of electrical power [58]. Carbon-based materials including graphite rods, granular graphite, and carbon paper are frequently utilized in biomass-fuel MFCs [59, 60].

Many surface modification techniques have been developed because of the flat surfaces of commercial carbon-based electrodes, which frequently have low electrochemical activity and biocompatibility. According to recent study, the modified candle soot CC electrode can change the CC electrodes’ hydrophobic surfaces into super-hydrophilic ones. In comparison to the unmodified electrode, the surface areas of the carbon cloths for bacterial adherence appeared to be enlarged by the sponge-like structure of the deposited candle soot. Bacterial proliferation benefited more from the accumulated candle soot’s super-hydrophilicity [61].

Additionally, studies have demonstrated that the use of conductive polymers, such as polypyrrole and polyaniline, can improve the quality of biofilms formed on the anode. The presence of positively charged nitrogen groups in the structure of these polymers enhances electrostatic attraction and increases the roughness of the electrode surface. Furthermore, by altering surface chemistry, adding electroactive groups to interface with microbial cells, and enhancing electrode surface quality, nanoparticles have also been used to increase electrical current in MFCs [62].

Coating of microbial fuel cells

Electrode resistances are one of the main issues limiting energy generation, fuel gas production, water desalination, wastewater treatment, cleaning of polluted water sources prevent MFCs from being used on a commercial basis. In many studies it is reported that coating of electrodes by mixing nanoparticles with microbes can maximize its potential [138]. There are many points which cannot be ignored during the application of MFC like the most important one is temperature and pH. The majority of the studies used microbial fuel cells in a 25–30 °C temperature range. The pH is another key factor; at pH values close to neutral, the highest density of power is observed [139].

Three components or elements are involved in the setup and functioning of the MFC. The first component is the anode, also known as the positive electrode. The utilization of nanomaterials enhances the anode’s functionality and efficiency—by boosting its surface area, electron transport, and electrical energy production. The application of nanomaterials that enhance cathode reactions, or ORR, is the main emphasis of the second factor, which is the cathode, or negative electrode. The third factor is the PEM proton membrane, which prevents oxygen from moving from the cathode to the anode by affecting proton transfer and using materials and nanoparticles in the installation and manufacturing processes [7]. The main focus is on how the anode, cathode, and membrane affect MFC performance and efficiency in different applications.

Compared to micro and large particles, nanoparticles have a higher surface area, which increases bacterial adherence and reduces resistance to electron transfer. Thus, the use of various nanomaterial shapes in MFC improves mass mobility within the system as well as the anode and cathode electron transfer processes. The cathode and anode used in MFCs can have an impact on a number of performance qualities, including microbial adhesion, oxidation of the organic substrate, and electron transfer rate (ETR). Anode and cathode in MFCs have been made of carbon, graphite, metal, polymer, metal oxides, and natural waste products [83].

Microbes involved in MFCs

Microbial fuel cell (MFC) devices utilize the metabolic processes of microbes to generate electricity from various organic substrates. Microorganisms oxidise organic materials in an MFC to produce electrons, which are then collected at an electrode. Microorganisms at an electrode in a MEC are given electrons, which they utilize to break down carbon dioxide or other substrates into products like hydrogen. To produce energy, MFCs specifically use microbes to catalyse electrochemical reactions [122].

MFCs typically have anodic and cathodic chambers that are separated by a proton exchange membrane (PEM)/salt bridge, though single chamber MFCs with or without an air–cathode are also possible [123]. In the anodic chamber, microorganisms oxidise the organic or inorganic substance to release protons and electrons (Figs. 2 and 3). The produced electrons are collected at the anode and transmitted through an external circuit to the cathode. Thus, MFCs are able to produce energy directly from a wide range of organic and inorganic chemicals using microbes as electrocatalysts [124].

Anaerobic and photosynthetic microorganisms

Numerous anaerobic and photosynthetic microorganisms have been used as electron acceptors and donors in microbial fuel cells. Organic substrates are broken down by microorganisms in the MFC, which also extracellularly transport electrons to an electrode surface. List of few microbes used in the MFC are Comamonas testosteroni, Raoultella ornithinolytica, Klebsiella pneumonia, Actinobacillus succinogenes, Aeromonas hydrophila, Alcaligenes faecalis, Pseudomonas aeruginosa, Clostridium beijerinckii, Desulfovibrio desulfuricans, Erwinia dissolven, Escherichia coli, Geobacter metallireducens, Geobacter sulfurreducens, Gluconobacter oxydans, Klebsiella pneumoniae, Lactobacillus plantarum, Proteus mirabilis, Pseudomonas aeruginosa, Rhodoferax ferrireducens, Shewanella oneidensis, Shewanella putrefaciens, Streptococcus lactis and many more [125].

MFCs are useful in many applications, such as sensors. An MFC-based sensor uses the microbes to detect and measure the amount of a certain chemical present in a sample. For example, if the MFC is used to detect glucose, the microorganisms within will consume glucose and generate energy as a byproduct [140]. The quantity of electricity created can then be used to compute the sample’s glucose content. MFC-based sensors have a number of advantages to conventional ones, such as the potential for usage in remote or inaccessible sites and the capacity to work under low-power settings. While MFC-based sensors offer promising potential, they also have some substantial disadvantages. One major limitation is their dependence on a constant supply of nutrients to sustain microbial activity. These sensors are highly sensitive to fluctuations in temperature and pH, which can affect their performance. Despite these challenges, MFC-based sensors remain promising for a wide range of applications, including environmental monitoring, medical diagnostics, and food safety testing [122]. The performance and dependability of these sensors are now being improved, and new applications for this technology are being explored.

By combining a novel anode design with the used in situ electrode-generation process, [141] have increased the potential limits of microbial energy generation by more than one order of magnitude. The fuel cell operates at a low emission level and has minimal operating costs because the use of dissolved artificial redox mediators is not essential [142]. According to studies, microbial power production presents opportunities for improvement [143]. The MFC technology is compared to the other energy producing options. To produce electrical output, bacteria use an anode as an electron acceptor [144]. The author demonstrated that the chosen organisms were capable of mediating the electron transfer either through direct bacterial transfer or by excretion of redox components, regardless of whether only attached or suspended bacteria were studied [145]. MFC technology may offer an innovative approach to reduce the operational costs of treatment plants for wastewater, making sophisticated wastewater treatment more accessible to both industrialized and developing countries [146]. MFCs can be used in low-power electronic devices like remote sensors as a reliable, long-lasting source of electricity [147]. A constructed wetland (CW) is a technique for treating water that uses natural processes to enhance the quality of the water [2]. The most environmentally friendly approach, which can replace traditional CWs and reduce system footprint by up to 20%, looked to be the CW system coupled with graphite-based anode MFC [148].

Genetically engineered microorganisms

Recent developments in molecular biology techniques have clarified electron transport channels and made it possible to engineer microbes to use biomass in MFCs to generate energy. To maximize biocatalysis in MFCs, a number of strategies, such as random, rational, and de novo designs, have been investigated for genomic engineering [63]. For instance, [64] developed a bioengineered microbial consortium consisting of Shewanella oneidensis and Klebsiella pneumoniae to efficiently harvest electricity from corn stalk hydrolysate. Engineered K. pneumoniae effectively fermented the hydrolysate to lactate by removing genes involved in the ethanol and acetate pathways and increasing lactate production and transport. This lactate was then used as fuel by S. oneidensis to generate power. Additionally, to improve the electron transfer efficiency of S. oneidensis, a heterologous flavins synthesis pathway from Bacillus subtilis was expressed [65]. The high efficiency with which these genetically modified microbial consortia generated energy from biomass hydrolysate underscores the potential of genetic engineering in modifying microorganisms for use in biomass-fueled MFCs.

Electroactive microorganisms (EAMs)

EAMs are essential components of MFCs. MFC is dependent on a special type of microorganism known as electroactive microorganisms (EAMs), which have a variety of metabolic pathways for breaking down organic materials and transferring the liberated electrons via extracellular electron transfer (EET) to the anodic electrode. A variety of names for these bacteria include electricigens, exoelectrogens, and anode-respiring bacteria (EAM). These bacteria are typically found in low-oxygen, low-nutrient settings that support metal-reducing metabolic pathways. If there is enough barrier to O2 transport to prevent aerobic microbes from dominating, they can also be found in well-studied microbial communities like sediment and wastewater. EAM are useful in bioremediation, bioelectrocatalysis, and MFCs. They are related to metal biogeochemistry. Moreover, EAM has the ability to both receive and transmit electrons between electrodes and solid surfaces. This capacity is employed in the process of bioelectrosynthesis, in which organic and inorganic molecules are reduced into electrobiocommodities with the help of electrons from the cathode [66]. Moreover, under certain circumstances, common bacterial strains that are not typically recognized for their capacity to transport electrons can behave similarly to electroactive microorganisms. Pseudomonas aeruginosa, for instance, is capable of producing phenazines, and Escherichia coli is capable of producing other mediators that aid in the passage of electrons to electrodes [67].

The two iron-reducing genera that have been isolated from sediments and studied thus far are Shewanella spp., facultative anaerobes that live in the high potential region of the iron reduction zone, and Geobacter spp. [68]; rigorous anaerobes with a reduced iron reduction potential prevail [69]. It is possible that, in comparison to other EAM that are present but are unable to flourish in a diverse consortium, this genus is the most adaptable and successful EAM in nutrient-rich environments. Numerous enrichment strategies have been developed in an effort to separate newly discovered electroactive microorganisms (EAM) from their naturally occurring microbe-rich habitats. Identifying these specialized organisms poses challenges due to their phylogenetic diversity, making it hard to develop molecular tools for accurate screening. Additionally, there are no specific genes, PCR primers, or FISH probes designed to target these microorganisms. Nevertheless, despite these barriers, ongoing discoveries of new electroactive microorganisms with external electroactivity continue to enrich our understanding of electron transfer mechanisms [70].

Characteristic features of microbes-based MFC-biosensors

Microbial fuel cell-based biosensors (MFCs) have a number of benefits over conventional sensing technologies. The advantages help explain why they are becoming more and more popular and have the potential for a wide range of uses. The following are some major benefits of MFC-based biosensors:

Real-time monitoring

Biosensors built on the MFC platform offer real-time monitoring capabilities. The biosensor can continually measure and record these electrical signals as microbes break down organic substrates and produce electrical current or potential. Real-time monitoring makes it possible for monitoring systems to be dynamic and responsive by providing quick detection and prompt reaction to changes in analyte concentrations [158].

High sensitivity and selectivity

The high sensitivity of MFC-based biosensors enables the detection of target analytes at low concentrations. The electrical output can be amplified by the metabolic activity of the microorganisms in the MFC, improving sensitivity and signal-to-noise ratio. Additionally, using particular microbial strains or genetically modified microorganisms can improve the biosensor’s selectivity, enabling the detection of particular analytes with less interference from other substances [159].

Cost-effectiveness and sustainability

MFC-based biosensors provide advantages in terms of cost and sustainability. Wastewater, organic waste, and renewable biomass are just a few examples of the various organic substrates that MFCs can use as fuel sources. Due to this feature, they are a more affordable option to conventional biosensors that rely on pricey chemicals or need to be replaced frequently. MFCs can also use organic waste streams as fuel, which helps with waste treatment and energy recovery, making them environmentally beneficial [160].

Remote monitoring, long-term operation and versatility

MFC biosensors can be used in remote or difficult-to-reach locations, making it possible to monitor environmental conditions in places where conventional sensors might be difficult to set up and maintain [57].

For continuous monitoring applications, MFC biosensors can function for extended periods of time without the requirement for periodic recalibration or reagent replenishment. Iwona Gajda et al. [161] have shown the long-term performance of three different MFC configurations utilizing ceramic membranes and fed with human urine. Individual units behaved differently over the course of a year, producing electricity up to 1.56 mW (22.3 W/m3) while losing performance by just 20% less than systems using traditional cation exchange membranes. After 580 days of operation, a 22-unit stack produced up to 21.4 mW (11.9 W/m3), demonstrating power recovery to the initial output levels, while a 3-module cascade (66 units overall) produced up to 75 mW (13.9 W/m3) of power, demonstrating only 20% power loss [162].

MFCs are capable of detecting a variety of analytes, such as heavy metals, organic molecules, and even changes in environmental variables like pH or temperature [163]. They are useful for a variety of industrial and environmental monitoring applications due to their versatility.

Applications, potentials and possibilities

Fuel cell technology has greatly benefited from nanotechnology. The incorporation of nanotechnology into MFCs has opened up new opportunities for increased performance and efficiency [71]. Researchers have been able to improve electron transfer rates, expand surface area for microbial growth, and optimize the overall efficiency of MFCs using nanomaterials including graphene, carbon nanotubes, and metal nanoparticles [72]. One of MFCs’ main benefits is their capacity to produce power from organic waste, which makes them a sustainable and environmentally beneficial energy source [73, 74]. This offers substantial potential for localized energy production in neglected or isolated locations as well as in wastewater treatment facilities with a surplus of organic waste [75, 76]. In the area of microbial fuel cells, nanotechnology presents a number of intriguing potentials and opportunities (MFCs). To be used in a variety of applications, MFCs need to overcome a few obstacles. The size and form of the reactors, the anodes, the power output, and the choice of appropriate microorganisms all pose serious concerns about the viability of employing MFCs in a variety of applications [77].

As shown in Fig. 4, MFCs have been adopted recently in bioremediation [127, 128], wastewater treatment [126], pollutant removal [129], microbial solar cells [130], bioelectricity generation [131], industrial chemicals recovery [132], hydrogen production [133], microbial desalination cells [134], energy recovery [135, 136] and sensors [137]. We have reviewed some of the important applications of MFCs in different sectors.

Applications of microbial fuel cells in different sectors/areas from environmental monitoring to power generation to brewing industries for a sustainable future

Microbes-based electrochemical sensors in medical diagnostics

MFCs are suited for use as electrochemical sensors because of their ability to generate electrical signals in response to changes in their surroundings. The anode is frequently colonized by microorganisms that oxidize organic compounds to create protons and electrons. The electrons travel to the cathode, where they combine with a terminal electron acceptor that contains oxygen to create a current. The microbes on the anode of MFCs can adjust their metabolism and produce different amounts of electrons in response to changes in the surrounding environment when they are used as electrochemical sensors. As a result, the MFC’s output of current could fluctuate. These variations are measurable and can be used as a signal to detect changes in the surrounding environment [164]. For instance, MFCs have been used to detect toxins in water, such as heavy metals or organic pollutants, by observing changes in the current the MFC generates in response to the presence of the contaminant. In addition to being used as sensors, MFCs have been researched as a method of powering other electronic devices or sensors in remote or low-resource areas. The ability of MFCs to generate electricity from organic chemicals found in the environment could potentially provide an economical and dependable power source for devices such as environmental monitoring systems in the future.

The main benefits of MFC technology are its cost and quick use. In reality, the system’s unique current change may quickly identify the presence of a pollutant in the feeding stream, negating the need for external transducers. Although pure cultures of naturally occurring microorganisms have been reported to be employed, mixed cultures of these bacteria are usually generated from anaerobic sludge [165]. It has been shown that using mixed cultures results in increased stability and higher performing MFC biosensors [166]. The researchers discussed about the electrochemical signature of the two representative exoelectrogens, which may be used as a tool for microbial community characterization [167].

During the enrichment process, the electroactive biofilm spontaneously grows on the biocompatible surface of the anode, removing the need for the laborious immobilization procedures of the sensing element [168]. One interesting aspect of MFC-based sensors is their potential for continuous, on-site operation that enables real-time monitoring. Furthermore, the electricity generated by the MFC enables the possibility of self-powering operations [169].

Medical diagnostics can be used to non-invasively identify a range of diseases and biomarkers. For instance, MFC-based biosensors can identify bacterial infections by tracking particular metabolic processes or by detecting the toxins produced by the bacteria. They can also detect illness-related analytes like glucose, lactate, or other biomarkers in physiological fluids, enabling real-time monitoring for disease management and individualised treatment. Wang et al. talked about the energy sources for the body sensor network, including fuel cells, supercapacitors, batteries, and power harvesters [170]. To improve energy and power density, operational dependability, and voltage performance for enzymatic fuel cells, Penven et al. reported this study into the application of electrochemical and nano structure expertise. The energy sources for wearable and implanted medical devices are highlighted by [171, 172]. The implantable devices help the body function, and they need an energy source to function [171, 172]. Dincer et al. provided insight into the disposable sensors’ potential future advances, dangers, and opportunities. These sensors are frequently used in medical diagnostics and monitoring [173]. Zebda et al. focused on the medical and physiological difficulties affecting the biocompatibility of biofuel cells operating inside a living body and emphasised recent advancements in the electrochemistry of biofuel cell technology [174].

In general, the application of MFCs as electrochemical sensors in medical diagnostics has promise for providing an accurate, targeted, and durable means of detecting alterations in the surrounding environment. More research is required to enhance MFC design and its sensor performance. The meaningful advancement of MFC research is thought to depend heavily on increased experimental repeatability and accuracy [49].

Biofilm formation and bacterial adhesion

Exoelectrogens act as active sites in anodic biofilms, where they facilitate the oxidation of organic substrates in MFCs. Through conduction, the anodic biofilms will accelerate the flow of electrons and the microbial adherence. Electron transport from the microbial biofilm to the electrode surface is limited in traditional anodes due to low microbial adhesion. This issue affects the MFC’s operation and lowers the power output. Better biofilm growth on the anode surface is made possible by nanomaterials, which offer a greater surface area for bacterial attachment. Overall MFC performance is improved by increased bacterial adhesion [91]. There have been reports of anode modifications using different nanomaterials, which produced MFCs with higher power density efficiency. Reduced graphene oxide nanosheets have been demonstrated in a recent study employing an MFC system to improve Shewanella putrefaciens-induced biofilms. These nanosheets allowed them to attain a power density of 240 mW m2, which is a huge improvement above the 0.015 mW m2 of the initial carbon-based anode [90]. Additionally, it makes it possible to create materials resistant to biofilm and anti-fouling coatings, which can extend the life of MFCs.

Cost-effective lightweight and portable devices

Nanotechnology allows for miniaturization, making it possible to create lightweight and portable MFCs [92]. These devices can be used for various applications, including powering handheld gadgets, sensors, and remote monitoring systems. Using nanomaterials, MFCs can potentially reduce costs associated with materials like platinum (used as a catalyst) and improve overall efficiency [93].

Wastewater treatment and energy generation

The ability of MFCs to produce bioenergy from a variety of substrates, including biomass wastes and urban and industrial wastewater, has garnered significant attention [94]. These systems allow for the removal of substances like nutrients, azo dyes, and even heavy metals through physical chemical reactions and bioelectrochemical reactions. Ammonia or struvite are effectively recovered from nitrogen and phosphorus-based compounds in biocathode chambers. MFC also eliminates azo dyes and metal ions like Cr (VI), Cu (II), Zn (II), or Fe (III) [95, 96].

Even though MFCs are superior to traditional wastewater treatment methods, they still need to be improved before being used on a big basis. MFCs augmented with nanomaterials, especially those using graphene oxide anodes, have demonstrated efficacy in eliminating impurities while concurrently producing power [97]. Because of its ability to serve two purposes, MFCs are useful for developing sustainable environmental solutions [27, 98].

Challenges in MFC-based biosensors

While microbial fuel cell (MFC)-based biosensors show a lot of promise, a number of issues need to be resolved to realize their full potential. The implementation of MFC-based biosensors will be dependable and widespread once these obstacles are overcome. To achieve precise and accurate biosensing capabilities, microbial populations within MFCs must be chosen and optimised. It can be difficult to locate and immobilise microorganisms that respond to target analytes in a robust and predictable way [149]. It is difficult to maintain the long-term stability and repeatability of MFC-based biosensors. Environmental conditions, substrate accessibility, and biofilm formation are just a few of the variables that might have an impact on microbial activity within the MFC. It is necessary to investigate strategies for preserving microbial stability, preventing biofilm detachment, and improving operating parameters [150]. The accuracy and specificity of MFC-based biosensors can be impacted by interference from and cross-sensitivity to other substances in the sample matrix. The sample may contain some chemicals that affect microbial metabolism or compete with the target analyte for electron transfer. MFC-based biosensors have produced encouraging results in the lab, but scaling the technology for use in real-world applications is still a difficult task. For field deployment and commercialization, MFCs must be scaled up while retaining their performance and stability [151]. The use of organic waste as fuel makes MFCs potentially cost-effective, but more advancements are needed to boost their energy efficiency and lower manufacturing costs. To maximize the energy output and minimize energy losses, improvements in electrode materials, system design, and operational parameter optimization are required, which will increase the viability of MFC-based biosensors from an economic standpoint [152]. Literature survey reveals the reports of several scientists to overcome the limiting factors of MFCs. Such attempts on anode biofilm, anode current collectors, anode structure and materials, anode configurations, anode number, cathode performance, medium pH, external resistance, substrate concentration, anode biofilm maturation, anode biocatalysts, anode mediators are reported [8, 153,154,155,156,157].

The widespread use of MFC-based biosensors in areas including environmental monitoring, medical diagnostics, and industrial processes will be made possible by addressing these difficulties through interdisciplinary research, innovation, and collaboration. By overcoming these obstacles, MFC technology can be used to its fullest extent for biosensing applications, resulting in dependable, sensitive, and affordable sensing systems.

Problems, challenges and considerations

In recent decades, business and individuals have consumed more electricity. The need for electricity is rising annually. Electrical energy storage is a major energy sector challenge. Existing batteries are unreliable for long-term storage [99]. Researchers are studying nanotechnology for energy storage. The latest energy innovations are supercapacitors, lithium-ion batteries, and hydrogen storage [100]. Electrodes for energy storage devices can be made in several ways. Nanotechnology components like light-emitting diodes use electricity efficiently [101, 102].

While MFCs are enough potent to be employed in industrial sector but still there are a lot of problems that need to be fixed before they can be used extensively. One of the main drawbacks of MFCs is its poor conductivity which prevents microorganisms from transferring electrons to electrodes [103]. Another major issue is that they do not produce as much electricity as traditional fuel cells do, which makes them less accessible and economically viable [104]. Thus, the need for volumetric expansion for large-scale power generation or large-scale wastewater treatment is affected, which further limits the implementation of this technology [105]. Even though the study on microbial energy technology is still in its infancy, there is much promise for this novel approach, which requires further investigation, particularly in relation to nanotechnology for more effective utilization. To achieve wider-scale adoption, it must also become more economical [106].

Moreover, microbial cells are utilized as electrochemical platforms to convert organic waste into energy. Despite the little quantity of fuel is produced but the method offers hope for waste mitigation [107]. Also, utilization of microbes to produce energy is an innovative approach to cleaning wastewater but activity loss, cost, and incomplete wastewater utilization are the main issues that need to be handled for practical application. To use this technology, further trials and tests are required.

MFCs have potential, but there are a number of issues that must be resolved before they are widely used. One of the primary problems is that, in comparison to traditional fuel cells, they produce less power, which restricts their scalability and economic feasibility [108]. Researchers are presently investigating methods to enhance the power density of MFCs by creating innovative nanomaterials and engineering fixes. The long-term stability and longevity of MFCs provide another difficulty because the existence of microbial biofilms might eventually cause performance loss [109]. Furthermore, the covering made of nanomaterials must not be harmful or interfere with the microbes’ ability tometabolize their food in MFCs.

Future prospects

MFCs can help replace fossil fuels with sustainable energy. They can help mitigate the adverse environmental effects of other renewable energy sources. Additionally, they can mitigate the adverse environmental effects of other renewable energy sources [4]. Innovation in this area is being fueled by developments in bioelectrochemistry, microbial engineering, and nanomaterial synthesis, which are opening the door for MFCs to be commercialized as a practical energy solution. Fuel cells have membranes that let hydrogen ions flow through the cell but block the passage of other atoms or ions, including oxygen. Businesses are utilizing nanotechnology to develop more effective membranes, which enables them to construct fuel cells that are lighter and more durable [110]. Catalysts play a crucial role in fuel cells by facilitating chemical reactions. Platinum is commonly used as a catalyst, but it is expensive. Platinum nanoparticles are being investigated as a way to cut costs by either substituting alternative materials for platinum or reducing the amount of platinum required [111]. Additionally, enhanced catalytic efficacy has been demonstrated by platinum nanoparticles of a particular size (about one micron). Additionally, tantalum and titanium oxide nanoparticles have been created by researchers to increase the iron–nitrogen–carbon fuel cell catalysts’ longevity [112]. High aspect ratios, increased surface area, and simple downsizing are made possible by nanotechnology. These qualities are essential for producing strong fuel cells for portable electronic devices, like laptops and handheld devices [113, 114].

Additionally, the conductivity of electrolytes can be increased by adding nanoparticles and nanocomposites, increasing the efficiency of MFCs (Fig. 5). Additionally, it is predicted that nanomaterials will speed up the development of biofilm on the electrode surface. Carbon-based nanomaterials can be used to prevent the typical carbon materials’ restriction of the driving power output area due to their relatively high internal resistance and poor electrical transmission channel. Nanoparticles not only improve conductivity but also provide a vast surface area for microbial adhesion and biofilm growth [72]. Exoelectrogenic bacteria, which are in charge of directly turning organic materials into electricity, can proliferate due to the increased surface area. Increased electricity generation and improved biocatalytic activity follow from this. Electrons can be transferred directly to the electrode surface by means of nanomaterials such as r-GO and carbon nanotubes (CNTs), which can serve as bridges between microorganisms and the electrode. Direct electron transfer, or DIET, is a method that avoids the electron shuttle channel and results in quicker electron transfer as well as increased energy conversion efficiency. These results are consistent with a work by Starowicz et al. that indicates greater bioelectricity generation and nutrient removal in MFCs using r-GO as an electrode, possibly as a result of improved DIET [115]. A variety of restrictions and challenges associated with MFC’s volumetric growth have limited its use in large-scale power generation and wastewater treatment. Sediments (S-MFC) and plant rhizospheres (P-MFC) were identified as the ideal natural hosts for MFC construction to get over these restrictions. Then, when the chance presented itself, MFCs were integrated to build wetlands (CW) to improve treatment efficiency and energy recovery. Furthermore, because CW-MFCs function as a technology for expeditious ecological restoration, they are exceptional in the context of environmental harmony [116].

Typical design and functional components (anode, cathode and pem) of nanomaterial-modified microbial fuel cell for enhanced performance

The scientific community is always working to lower the emissions of organic waste because it presents such a significant problem. Thus, COD was removed from waste water by employing bacteria present in the waste water using Microbial Fuel Cell technology, while energy was also produced concurrently. It has been demonstrated that this is a useful, innovative strategy with two advantages. According to a study, the Zn–Cu electrode has significantly more potential for wastewater treatment and bioelectricity generation than the aluminum electrode. It will take further research to address issues at the most fundamental level before such concepts can be implemented. This is a great concept as it addresses one of the major concerns of upcoming decades [117]. Whereas, a recent study revealed that A. Xylosoxidans and S. Maltophilia have great potential to achieve high voltage and electric current. So, by connecting such MFCs in series output power of electronic devices can be improved. Therefore, more study might aid in the development of electronic devices that have the ability to store energy, meaning they can be utilized to generate energy without requiring a lot of electrical power. To implement such ideas in the real world, the industrial sector must thoroughly examine this notion [118]. Furthermore, as Fe–N-S-C nanozymes with MOFs are carriers inspired by biological enzyme systems, it is important to investigate the influence of nanozymes on MFC efficiency as it can be employed as a unique technique for creating high-performance MFC anodes from a biomimicry perspective [119]. Additionally, new and distinctive qualities produced by nanotechnology on nanostructured materials like as metal, graphene, carbon nanotubes (CNTs), conductive polymers, activated carbon fiber, and others can be used to improve MFC’s ability to generate energy [120]. Furthermore, the potential recovery of value-added goods may contribute to MFCs’ increased financial sustainability. As a result, the cost of metal recovery can be decreased by effectively extracting heavy metals from the cathode utilizing a carbon source, such as the wastewater substrate at the anode. Microorganism growth has been demonstrated to be slowed down by an excess of heavy metal concentration. Therefore, figuring out these metals’ ideal concentration level can increase system performance and save operating expenses [121]. We believe that there is hope for MFCs enabled by nanotechnology, and research is still being done to improve the efficiency and dependability of these devices.

Conclusion

Nanotechnology has revolutionized the field of MFCs, offering promising solutions to address current limitations and unlock the full potential of this sustainable energy technology. By enhancing electron transfer rates, expanding microbial adhesion surfaces, and optimizing anode, cathode, and membrane materials, nanotechnology has significantly improved the performance and efficiency of MFCs. Additionally, advancements in microbial engineering, including the use of genetically modified electroactive microorganisms, have opened new avenues for increasing extracellular electron transfer (EET) efficiency and enhancing bioenergy production.

Despite these promising advancements, several challenges continue to hinder the large-scale commercialization of MFCs. Issues such as low power output, high operational costs, and limited electron transfer efficiency between microbes and electrodes must be addressed to make MFCs more competitive in the energy market. This review highlights a systematic and integrated approach that combines nanotechnology, microbial engineering, and innovative system designs to overcome these challenges. Future research should focus on developing cost-effective materials, optimizing microbial consortia, and exploring novel nanomaterials that can further improve MFC performance. Moreover, MFC-based biosensors, with enhanced sensitivity and long-term operational stability, present exciting opportunities for applications in environmental monitoring, medical diagnostics, and industrial processes. The integration of nanotechnology with MFCs not only enhances their energy generation capabilities but also paves the way for their broader adoption in diverse sectors.

In conclusion, the amalgamation of nanotechnology, microbial engineering, and optimized system designs holds the potential to transform MFCs into reliable, scalable, and cost-effective energy solutions. Continued research and innovation in this field can contribute significantly toward addressing global energy challenges and advancing the transition to cleaner and more sustainable energy sources.

Data availability

No datasets were generated or analysed during the current study.

References

-

Nasrollahzadeh M, Sajadi SM, Sajjadi M, Issaabadi Z. An introduction to nanotechnology. In: Interface science and technology. Amsterdam: Elsevier; 2019. p. 1–27.

-

Manesh MHK, Davadgaran S, Rabeti SAM. Experimental study of biological wastewater recovery using microbial fuel cell and application of reliability and machine learning to predict the system behavior. Energy Convers Manage. 2024;314: 118658.

-

Sayed ET, Parambath JB, Abdelkareem MA, Alawadhi H, Olabi AG. Ni-based metal organic frameworks doped with reduced graphene oxide as an effective anode catalyst in direct ethanol fuel cell. J Alloy Compd. 2024;976: 173194.

-

Unuofin JO, Iwarere SA, Daramola MO. Embracing the future of circular bio-enabled economy: unveiling the prospects of microbial fuel cells in achieving true sustainable energy. Environ Sci Pollut Res. 2023;30(39):90547–73.

-

Xia C, Zhang D, Pedrycz W, Zhu Y, Guo Y. Models for microbial fuel cells: a critical review. J Power Sources. 2018;373:119–31.

-

Chouhan RS, Gandhi S, Verma SK, Jerman I, Baker S, Štrok M. Recent advancements in the development of two-dimensional nanostructured based anode materials for stable power density in microbial fuel cells. Renew Sustain Energy Rev. 2023;188: 113813.

-

Abd-Elrahman NK, Al-Harbi N, Basfer NM, Al-Hadeethi Y, Umar A, Akbar S. Applications of nanomaterials in microbial fuel cells: a review. Molecules. 2022;27(21):7483.

-

Sonawane AV, Rikame S, Sonawane SH, Gaikwad M, Bhanvase B, Sonawane SS, Gaikwad R. A review of microbial fuel cell and its diversification in the development of green energy technology. Chemosphere. 2024;350:141127.

-

Alshammari AS. Role of graphene-silver nanocomposite as anode to boost single-chamber microbial fuel cell performance. Chem Afr. 2024;7:4555–67.

-

Hassan Q, Viktor P, Al-Musawi TJ, Ali BM, Algburi S, Alzoubi HM, Jaszczur M. The renewable energy role in the global energy transformations. Renewable Energy Focus. 2024;48: 100545.

-

Saravanan A, Karishma S, Kumar PS, Yaashikaa PR, Jeevanantham S, Gayathri B. Microbial electrolysis cells and microbial fuel cells for biohydrogen production: current advances and emerging challenges. Biomass Conversion and Biorefinery. 2020;1–21.

-

Jalili P, Ala A, Nazari P, Jalili B, Ganji DD. A comprehensive review of microbial fuel cells considering materials, methods, structures, and microorganisms. Heliyon. 2024;10: e25439.

-

Walter XA, You J, Winfield J, Bajarunas U, Greenman J, Ieropoulos IA. From the lab to the field: Self-stratifying microbial fuel cells stacks directly powering lights. Appl Energy. 2020;277: 115514.

-

Tsekouras GJ, Deligianni PM, Kanellos FD, Kontargyri VT, Kontaxis PA, Manousakis NM, Elias CN. Microbial fuel cell for wastewater treatment as power plant in smart grids: Utopia or reality? Frontiers in Energy Research. 2022;10: 843768.

-

Assad H, Kaya S, Kumar PS, Vo DVN, Sharma A, Kumar A. Insights into the role of nanotechnology on the performance of biofuel cells and the production of viable biofuels: A review. Fuel. 2022;323: 124277.

-

Oliveira VB, Pinto AMFR. Microbial fuel cells: from fundamentals to applications. Front Energy Res. 2019;7:113.

-

Yang Q, Luo D, Liu X, Guo T, Zhao X, Zheng X, Wang W. Improving the anode performance of microbial fuel cell with carbon nanotubes supported cobalt phosphate catalyst. Bioelectrochemistry. 2021;142: 107941.

-

Salar-García MJ, Ortiz-Martínez VM. Nanotechnology for wastewater treatment and bioenergy generation in microbial fuel cells. In: Advanced research in nanosciences for water technology. 2019;341–362.

-

Chen BY, Tsao YT, Chang SH. Cost-effective surface modification of carbon cloth electrodes for microbial fuel cells by candle soot coating. Coatings. 2018;8(12):468.

-

Martínez-Sánchez C, Bustos EB, Sandoval-González A. Influence of nanomaterials in combined microbial fuel cell-electro-fenton systems as a sustainable alternative for electricity generation and wastewater treatment. In: Innovations in environmental biotechnology. Singapore: Springer Nature Singapore; 2022. p. 677–704.

-

Zhao CE, Gai P, Song R, Chen Y, Zhang J, Zhu JJ. Nanostructured material-based biofuel cells: recent advances and future prospects. Chem Soc Rev. 2017;46(5):1545–64.

-

Lazar NE, Mazkad D, Kharti H, Yalcinkaya F, Pietrelli A, Ferrara V, Touach N, Benzaouak A, Mahi ME, Lotfi EM. Maximizing power generation in single-chamber microbial fuel cells: the role of LiTa0. 5Nb0. 5O3/g-C3N4 photocatalyst. Mater Renew Sustain Energy. 2024;13(2):209–18.

-

Singh A, Kaushik A. Sustained energy production from wastewater in microbial fuel cell: effect of inoculum sources, electrode spacing and working volume 3. Biotech. 2021;11(7):344.

-

Minutillo M, Di Micco S, Di Giorgio P, Erme G, Jannelli E. Investigating air-cathode microbial fuel cells performance under different serially and parallelly connected configurations. Energies. 2021;14:5116.

-

Helder M, Strik DP, Hamelers HV, Buisman CJ. The flat-plate plant-microbial fuel cell: the effect of a new design on internal resistances. Biotechnol Biofuels. 2012;5(70):1–1.

-

Tavakolian M, Taleghani HG, Khorshidian M. New design of benthic microbial fuel cell for bioelectricity generation: Comparative study. Int J Hydro Energy. 2020;45(43):23533–42.

-

Khandaker S, Das S, Hossain MT, Islam A, Miah MR, Awual MR. Sustainable approach for wastewater treatment using microbial fuel cells and green energy generation—a comprehensive review. J Mol Liq. 2021;344: 117795.

-

Wu S, Li H, Zhou X, Liang P, Zhang X, Jiang Y, Huang X. A novel pilot-scale stacked microbial fuel cell for efficient electricity generation and wastewater treatment. Water Res. 2016;98:396–403.

-

Kaur R, Marwaha A, Chhabra VA, Kim KH, Tripathi SK. Recent developments on functional nanomaterial-based electrodes for microbial fuel cells. Renew Sustain Energy Rev. 2020;119: 109551.

-

Srivastava RK, Sarangi PK, Vivekanand V, Pareek N, Shaik KB, Subudhi S. Microbial fuel cells for waste nutrients minimization: recent process technologies and inputs of electrochemical active microbial system. Microbiol Res. 2022;265: 127216.

-

Kamali M, Aminabhavi TM, Abbassi R, Dewil R, Appels L. Engineered nanomaterials in microbial fuel cells–recent developments, sustainability aspects, and future outlook. Fuel. 2022;310: 122347.

-

Mishra A, Bhatt R, Bajpai J, Bajpai AK. Nanomaterials based biofuel cells: a review. Int J Hydrogen Energy. 2021;46(36):19085–105.

-

Shiomi N. The strategy and future of biotechnology in protecting the global environment. In: Bioremediation for global environmental conservation. IntechOpen. 2023.

-

Tawalbeh M, Javed RMN, Al-Othman A, Almomani F. The novel advancements of nanomaterials in biofuel cells with a focus on electrodes’ applications. Fuel. 2022;322: 124237.

-

Menandro LMS, Cantarella H, Franco HCJ, Kölln OT, Pimenta MTB, Sanches GM, Carvalho JLN. Comprehensive assessment of sugarcane straw: implications for biomass and bioenergy production. Biofuels, Bioprod Biorefin. 2017;11(3):488–504.

-

Moradian JM, Fang Z, Yong YC. Recent advances on biomass-fueled microbial fuel cell. Bioresour Bioprocess. 2021;8:1–13.

-

Hoang AT, Nizetic S, Ng KH, Papadopoulos AM, Le AT, Kumar S, Hadiyanto H. Microbial fuel cells for bioelectricity production from waste as sustainable prospect of future energy sector. Chemosphere. 2022;287: 132285.

-

Anukam A, Berghel J. Biomass pretreatment and characterization: a review. In: Biotechnological applications of biomass. 2021; pp. 1–17.

-

Ballestas ER, Bortoluzzi EC, Minervino AHH, Palma HH, Neckel A, Ramos CG, Moreno-Ríos AL. Power generation potential of plant microbial fuel cells as a renewable energy source. Renewable Energy. 2024;221: 119799.

-

Apollon W, Kamaraj SK, Rodríguez-Fuentes H, Gómez-Leyva JF, Vidales-Contreras JA, Mardueño-Aguilar MV, Luna-Maldonado AI. Bio-electricity production in a single-chamber microbial fuel cell using urine as a substrate. Biofuels. 2024;15(6):665–75.

-

Abnisa F. Aqueous phase formation in biomass pyrolysis: unravelling heating rate effects and introducing sodium sulphate pyrolysis oil refining. Sep Purif Technol. 2024;341: 126778.

-

Karthikeyan PK, Bandulasena HCH, Radu T. A comparative analysis of pre-treatment technologies for enhanced biogas production from anaerobic digestion of lignocellulosic waste. Ind Crops Prod. 2024;215: 118591.

-

Song TS, Hou S, Zhang J, Wang H, Xie J. Production of electricity from rice straw with different pretreatment methods using a sediment microbial fuel cell. Int J Electrochem Sci. 2018;13(1):461–71.

-

Wagner AO, Lackner N, Mutschlechner M, Prem EM, Markt R, Illmer P. Biological pretreatment strategies for second-generation lignocellulosic resources to enhance biogas production. Energies. 2018;11(7):1797.

-

Pandit S, Savla N, Sonawane JM, Sani AMD, Gupta PK, Mathuriya AS, Prasad R. Agricultural waste and wastewater as feedstock for bioelectricity generation using microbial fuel cells: recent advances. Fermentation. 2021;7(3):169.

-